Precise compression, CO2 compressor zero emission commitment: tailor-made solutions for you

Brief introduction to the importance of co2 compressors in industrial production and environmental protection

In the field of industrial production, co2 compressors play a vital role. They are indispensable equipment in many industries such as chemical, food processing, and pharmaceuticals for processing, transporting and storing CO2. As an important industrial gas, CO2 is widely used in refrigeration, gas shielded welding, beverage carbonation, chemical production and other links. The efficient and stable operation of the compressor is directly related to the efficiency of these process flows and product quality.

Specifically, co2 compressors can ensure the stable storage and transportation of gas under high pressure to meet the gas needs in various industrial production processes. In chemical production, they provide the necessary pressure and flow conditions for chemical reactions to ensure the smooth progress of the reaction. In food processing, compressors provide a stable gas source for beverage carbonation to ensure the taste and quality of the product. In addition, in gas shielded welding, CO2 as a shielding gas can effectively prevent weld oxidation and improve welding quality.

In the field of environmental protection, the application of co2 compressors is also of great significance. With the intensification of global climate change, reducing greenhouse gas emissions has become a global consensus. As one of the main greenhouse gases, the control of carbon dioxide emissions is of great significance for mitigating climate change. Carbon co2 compressor can reduce energy consumption and emissions during gas processing and transportation through efficient and energy-saving compression technology. At the same time, they can also compress and store captured carbon dioxide, providing basic support for subsequent carbon capture, utilization and storage (CCUS) technology.

In addition, the application of carbon co2 compressor in the field of environmental protection is also reflected in promoting the development of clean energy. For example, in the hydrogen energy industry, carbon co2 compressor can be used for gas compression and separation in the process of hydrogen purification to improve the purity and production efficiency of hydrogen. In the field of biomass energy, compressors can also be used for gas compression and transportation in the process of biomass gasification to provide support for the efficient use of biomass energy.

In summary, carbon co2 compressor play an irreplaceable role in industrial production and environmental protection. They not only ensure the smooth progress of industrial production, but also provide strong support for reducing greenhouse gas emissions and promoting the development of clean energy. With the continuous advancement of technology and the continuous expansion of applications, carbon co2 compressor will play a more important role in the future.

Emphasize the current market’s urgent need for efficient and environmentally friendly compressors

Against the backdrop of rapid global economic development and growing awareness of environmental protection, the market demand for efficient and environmentally friendly carbon co2 compressor has become unprecedentedly urgent. This demand not only stems from the upgrading and transformation of traditional industrial production, but is also closely linked to the sustainable development strategy under the challenge of global climate change.

First, from the perspective of industrial production, with the iteration of technology and industrial upgrading, the requirements for production efficiency and quality in various industries are constantly increasing. Traditional compressors have many deficiencies in terms of energy consumption, noise, maintenance costs, etc., and are no longer able to meet the stringent standards of modern industrial production. Efficient and environmentally friendly carbon co2 compressor can significantly reduce energy consumption and greenhouse gas emissions by adopting advanced compression technology and intelligent control systems, while improving compression efficiency and stability, becoming key equipment to promote industrial green transformation.

Secondly, in the face of the severe challenges of global climate change, governments have introduced relevant policies to limit greenhouse gas emissions and encourage the development of clean energy and low-carbon technologies. As one of the important tools for achieving carbon reduction targets, the efficient and environmentally friendly performance of carbon co2 compressor is directly related to the control of carbon emissions and the achievement of emission reduction targets. Therefore, the market demand for efficient and environmentally friendly compressors is not only the inherent demand of the company’s own transformation and upgrading, but also an inevitable choice to respond to national policies and fulfill social responsibilities.

In addition, with the increasing environmental awareness of consumers, green consumption has become a new trend. More and more consumers tend to choose products of companies that use environmentally friendly technologies and equipment in the production process. Therefore, in order to enhance their brand image and market competitiveness, companies also need to actively adopt efficient and environmentally friendly carbon co2 compressor to meet consumers’ green consumption needs.

The current market demand for efficient and environmentally friendly compressors is already very urgent. This demand not only stems from the transformation and upgrading needs of industrial production itself, but is also closely linked to the sustainable development strategy and consumer green consumption trends under the background of global climate change. Therefore, the development and application of efficient and environmentally friendly carbon co2 compressor is not only the need for the company’s own development, but also an inevitable requirement for promoting social progress and sustainable development.

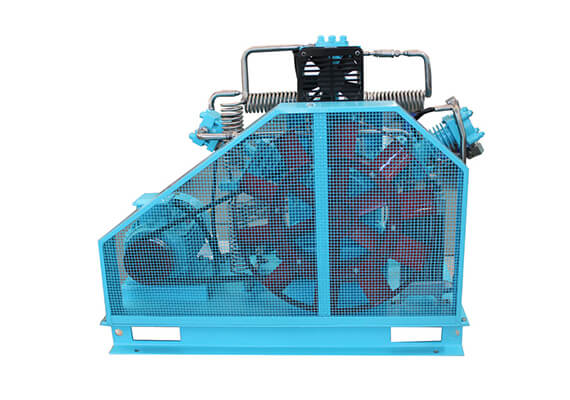

Product Features and Advantages: Efficient and Environmentally Friendly Carbon co2 compressor

Driven by the current market demand, our efficient and environmentally friendly carbon co2 compressor have won the favor of customers with their unique product characteristics and significant advantages. The following is a detailed explanation of the characteristics and advantages of this product:

- High efficiency and energy saving

Advanced compression technology: Adopt advanced technologies such as multi-stage compression and frequency conversion regulation to achieve efficient compression and transportation of gas. Multi-stage compression technology can reduce the power consumption of each stage of compression and improve the overall compression efficiency; while variable frequency regulation can adjust the operating frequency of the compressor according to actual needs to avoid unnecessary energy consumption.

Intelligent control system: Equipped with an advanced intelligent control system, it can monitor the working status of the compressor in real time and automatically adjust the operation of the compressor according to the set parameters to ensure that the equipment is always in the best working condition. This not only improves the compression efficiency, but also reduces maintenance costs.

- Environmental protection and emission reduction

Zero emission design: The compressor adopts advanced sealing design and optimized cooling system to ensure that the gas will not leak during the compression process, while reducing the use of cooling water and achieving zero emissions. This not only meets the current environmental protection requirements, but also saves water resources for enterprises.

Significant energy-saving effect: Due to the use of advanced compression technology and intelligent control systems, the compressor can significantly reduce energy consumption and greenhouse gas emissions during operation. This not only helps enterprises fulfill their social responsibilities, but also saves a lot of electricity expenses for enterprises.

- Tailor-made

Highly customized: We provide highly customized services, and customize the size, power, control system, etc. of the compressor according to the actual needs of customers to ensure that the equipment can be perfectly integrated into the customer’s production process.

Flexible response to various working conditions: The compressor can adapt to a variety of complex working conditions such as high temperature, high pressure, high humidity, etc., ensuring stable operation in various environments. This provides enterprises with greater production flexibility and reliability.

- Easy maintenance

Modular design: The compressor adopts a modular design, which makes the disassembly and repair of the equipment easier and more convenient. This reduces maintenance costs and improves the availability of equipment.

Remote monitoring and maintenance: Through the intelligent control system, customers can remotely monitor the operating status of the compressor and discover and solve problems in a timely manner. In addition, we also provide remote maintenance services to ensure that the equipment can be quickly repaired when problems arise.

In summary, our efficient and environmentally friendly carbon co2 compressor have significant advantages in high efficiency and energy saving, environmental protection and emission reduction, tailor-made and easy maintenance. These advantages make our products highly competitive in the market and can meet the diverse needs of customers.

Technical advantages and performance: efficient and environmentally friendly carbon dioxide compressor

Against the background of the growing demand for efficient and environmentally friendly equipment in the current industrial production and environmental protection fields, the efficient and environmentally friendly carbon dioxide compressor we launched has become a leader in the market with its outstanding technical advantages and excellent performance. The following is a detailed description of the technical advantages and performance of this product:

- Technical advantages

Advanced compression technology: We use advanced technologies such as multi-stage compression and variable frequency regulation to ensure that the gas can be efficiently and stably transported during the compression process. Multi-stage compression technology reduces the power consumption required for each stage of compression by gradually increasing the pressure of the gas, thereby improving the overall compression efficiency. The variable frequency regulation technology can automatically adjust the operating frequency of the compressor according to the actual gas demand, avoiding unnecessary energy consumption and wear.

Intelligent control system: We have equipped the compressor with an advanced intelligent control system, which can monitor the working status of the compressor in real time, including key parameters such as pressure, temperature, and vibration. Through data analysis, the system can automatically adjust the operating parameters of the compressor to ensure that the equipment is always in the best working condition. This not only improves the compression efficiency, but also extends the service life of the equipment.

Environmentally friendly design: We pay attention to the environmental performance of our products. By adopting advanced sealing technology and optimized cooling system, we ensure that the gas will not leak during the compression process, while reducing the use of cooling water. This not only meets the current environmental protection requirements, but also saves water resources for enterprises and reduces operating costs.

- Performance

Efficient energy saving: Due to the use of advanced compression technology and intelligent control system, our compressors can significantly reduce energy consumption during operation. Compared with traditional compressors, our products can save a lot of electricity under the same gas demand, reducing the company’s electricity expenses.

Stable operation: Our compressors use high-strength, corrosion-resistant materials and advanced manufacturing processes to ensure the stable operation of the equipment under harsh working conditions. Whether in high temperature, high pressure or high humidity environment, our compressors can maintain excellent performance and provide enterprises with reliable gas supply.

Convenient maintenance: We adopt a modular design, which makes the disassembly and maintenance of the compressor easier and more convenient. In addition, we also provide comprehensive after-sales service and remote monitoring and maintenance services to ensure that the equipment can be quickly repaired when problems occur, reducing the company’s downtime and maintenance costs.

Noise reduction: We focus on the noise control of our products. By adopting advanced noise reduction technology and materials, we reduce the noise level of the compressor during operation. This not only improves the working environment of employees, but also reduces the noise pollution to the surrounding environment.

Customer Cases and Feedback: Excellent Performance of High-efficiency and Environmentally Friendly co2 compressors in Practical Applications

Our high-efficiency and environmentally friendly co2 compressors have won wide recognition and praise in the market with their outstanding technical advantages and excellent performance. The following are some customer cases and feedback, showing the excellent performance of our products in practical applications.

- Chemical Industry Cases

A large chemical company introduced our high-efficiency and environmentally friendly co2 compressors for gas compression and transportation in its production process. After the introduction of this equipment, the company’s production efficiency has been significantly improved, and the gas transportation efficiency has increased by nearly 30%. At the same time, because the intelligent control system of the compressor can monitor the operating status of the equipment in real time, timely discover and solve problems, and avoid production interruptions caused by equipment failure. In addition, the environmental performance of the equipment also meets the environmental protection requirements of the company, saving water resources and electricity expenses for the company. Customer feedback said that our compressors not only improved production efficiency, but also reduced operating costs, which is an important support for the upgrading and transformation of enterprises.

- Cases in the food processing industry

A well-known food processing company selected our efficient and environmentally friendly carbon dioxide compressor for the carbonation process of its beverage production line. After the introduction of the equipment, the taste and quality of the beverages have been significantly improved, and consumer satisfaction has been greatly improved. At the same time, due to the multi-stage compression and frequency conversion regulation technology of the compressor, the energy consumption of the equipment has been greatly reduced, saving the company a lot of electricity expenses. Customer feedback said that our compressor not only improves the quality of beverages, but also reduces production costs and enhances the company’s market competitiveness.

- Cases in the pharmaceutical industry

A pharmaceutical company introduced our efficient and environmentally friendly carbon dioxide compressor for gas protection and drug storage in its production process. After the introduction of the equipment, the company’s drug production quality has been significantly improved, and the purity and stability of the drugs have been guaranteed. At the same time, the intelligent control system of the compressor can monitor the operating status of the equipment in real time, avoiding production interruptions and quality problems caused by equipment failure. Customer feedback said that our compressor not only improves the production quality of drugs, but also ensures the stability and reliability of the production process. It is an important tool for enterprises to improve production efficiency and reduce operating costs.

- Customer feedback summary

The customers in the above cases all gave high praise to our efficient and environmentally friendly carbon co2 compressor. They generally believe that our products have significant advantages in improving production efficiency, reducing operating costs, and ensuring production quality. At the same time, the environmental performance of the products also meets the current environmental protection requirements, saving water resources and electricity expenses for enterprises. In addition, we also provide comprehensive after-sales service and remote monitoring and maintenance services to ensure that the equipment can be quickly repaired when problems occur, reducing the company’s downtime and maintenance costs. Customers have expressed that they will continue to choose our products and recommend them to other companies in need.

Summary and Outlook: High-efficiency and environmentally friendly carbon co2 compressor-leading the innovation of future industrial gas compression technology

Through in-depth analysis and explanation of the technical advantages, performance, customer cases and feedback of high-efficiency and environmentally friendly carbon co2 compressor, it is not difficult to find that this innovative product has shown great potential and value in the fields of industrial production and environmental protection. Its excellent technical performance, efficient energy utilization, excellent environmental protection characteristics and wide applicability have won it wide recognition and praise in the market.

Summary

Technological innovation leads development: Our high-efficiency and environmentally friendly carbon co2 compressor adopt advanced technologies such as multi-stage compression, variable frequency regulation, and intelligent control to achieve efficient and stable compression and transportation of gas. The innovative application of these technologies not only improves the compression efficiency and stability of the equipment, but also reduces energy consumption and emissions, meeting the current environmental protection requirements.

Excellent performance meets demand: In actual applications, our compressors have demonstrated outstanding performance. Whether it is the production needs of the chemical industry or the specific requirements of industries such as food processing and pharmaceuticals, our products can provide a stable and reliable gas supply to meet the diverse needs of customers.

Customer feedback verifies value: The successful cases and positive feedback from many customers further verify the excellent performance and value of our efficient and environmentally friendly carbon co2 compressor in actual applications. Customers generally believe that our products have significant advantages in improving production efficiency, reducing operating costs, and ensuring production quality, and are a powerful assistant for them to upgrade and transform and improve their market competitiveness.

Prospects

Looking to the future, with the accelerated advancement of global industrialization and urbanization, and the continuous enhancement of environmental awareness, the demand for efficient and environmentally friendly gas compression equipment will continue to grow. We will continue to uphold the concept of innovation, green and sustainable development, and continue to develop and promote more advanced and environmentally friendly gas compression technologies to provide customers from all walks of life with better quality, efficient and environmentally friendly gas compression solutions.

At the same time, we will also strengthen cooperation and exchanges with well-known domestic and foreign companies and scientific research institutions to jointly promote the innovation and development of gas compression technology. We believe that through our joint efforts and unremitting pursuit, our efficient and environmentally friendly carbon co2 compressor will play a more important role in the future field of industrial gas compression technology and make greater contributions to the development of global industrial production and environmental protection.

Appendix: Detailed technical parameters and application fields of efficient and environmentally friendly carbon co2 compressor

- Detailed technical parameters

In order to help customers better understand our efficient and environmentally friendly carbon co2 compressor, some key technical parameters are listed below for your reference:

Model: According to customer needs, we provide a variety of compressor models to meet the needs of different application scenarios.

Compression capacity: Our compressors have strong compression capacity and can handle various gas compression needs from low pressure to high pressure. The specific compression capacity depends on the model and configuration to meet the different needs of customers.

Energy consumption: Due to the use of advanced compression technology and intelligent control system, our compressors can significantly reduce energy consumption during operation. Specific energy consumption data can be customized and optimized according to actual working conditions and customer needs.

Noise: We pay attention to the noise control of products, and reduce the noise level of compressors during operation by adopting advanced noise reduction technology and materials. The specific noise value can be adjusted according to customer needs and actual application scenarios.

Environmental performance: Our compressors meet current environmental protection requirements. By adopting advanced sealing technology and optimized cooling systems, we ensure that the gas will not leak during the compression process, while reducing the use of cooling water. In addition, we also provide a variety of environmental protection options, such as the use of renewable energy, to meet customers’ environmental protection needs.

Intelligent control system: Our compressors are equipped with advanced intelligent control systems that can monitor the operating status of the equipment in real time, including key parameters such as pressure, temperature, and vibration. Through data analysis, the system can automatically adjust the operating parameters of the compressor to ensure that the equipment is always in the best working condition. At the same time, we also provide remote monitoring and maintenance services to ensure that the equipment can be quickly repaired when problems occur.

- Application areas

Our efficient and environmentally friendly carbon co2 compressor have a wide range of applications, including but not limited to the following aspects:

Chemical industry: used for gas compression and transportation in chemical production processes, such as gas supply for production lines such as synthetic ammonia, urea, and methanol.

Food processing industry: used for the carbonation process of beverage production lines, and gas protection in food packaging, etc.

Pharmaceutical industry: used for gas protection and storage in the production process of drugs, and gas filling in drug packaging, etc.

Refrigeration industry: used for gas compression and delivery in refrigeration systems, such as refrigeration cycles of air conditioners, cold storage and other equipment.

Other industries: such as gas compression and delivery needs in industries such as oil, natural gas, electricity, and metallurgy.

The above are only examples of some application areas. In fact, our efficient and environmentally friendly carbon co2 compressor can be customized and optimized according to customer needs to meet the needs of different industries and application scenarios. We look forward to working hand in hand with our customers to explore more innovative applications and make greater contributions to the development of global industrial production and environmental protection.

Please note that the above technical parameters and application areas are for reference only. The specific data and application range may vary depending on the product model, configuration and customer needs. If you have any questions or needs, please feel free to contact us, we will wholeheartedly provide you with professional consultation and services.