LPG compressor vs natural gas compressor: main differences and application scenarios

In the grand picture of the energy industry, gas compression technology plays a pivotal role. Whether it is liquefied petroleum gas (LPG) or natural gas, efficient and safe compression equipment is an indispensable core in every link from its extraction, processing, storage, transportation to final use. LPG compressors and natural gas compressors, as two major types of industrial gas compression equipment, are both committed to increasing the pressure of gas to meet different process requirements. However, due to the significant differences in the physical and chemical properties of the media they process – LPG and natural gas – these two compressors have their own unique characteristics in design principles, material selection, safety protection standards, operation and maintenance requirements, and even final application scenarios. This article aims to deeply analyze the basic definitions and core differences between LPG compressors and natural gas compressors, elaborate on their specific applications in their respective fields, and provide industry professionals with key factors that need to be comprehensively considered when selecting equipment, in order to provide valuable reference for the healthy development of the energy industry.

Basic definitions of LPG compressors and natural gas compressors

To understand the essence of these two compressors, we must first start with the gas media they process.

LPG compressor:

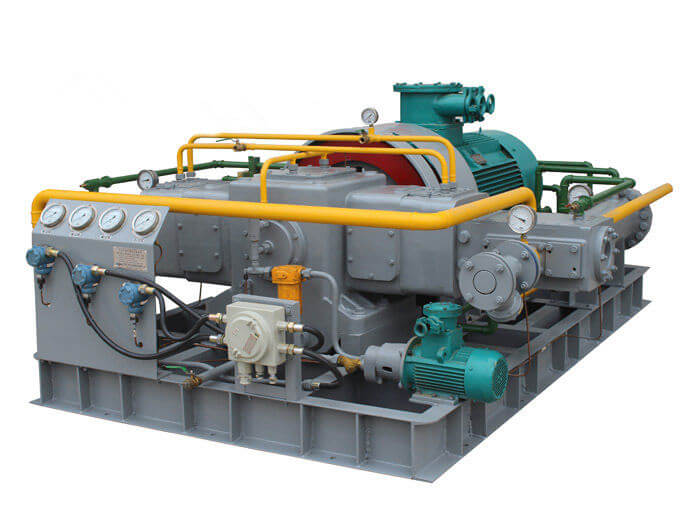

-1.png)

LPG, or liquefied petroleum gas, is a mixture of light hydrocarbons produced during the refining process of crude oil in a refinery or during the extraction and processing of natural gas. Its main components are usually propane (C3H8) and butane (C4H10), and may contain a small amount of unsaturated hydrocarbons such as propylene and butene. At normal temperature and pressure, LPG exists in a gaseous state; however, it can easily change from a gaseous state to a liquid state by applying a relatively small pressure (usually between 0.5 MPa and 1.5 MPa) or lowering the temperature. LPG compressors are born for this purpose. It is a mechanical device specially designed for compressing, transporting, recovering and pressurizing LPG vapor.

The working principle of LPG compressors is to convert LPG in a low-pressure gaseous state into pressure energy through mechanical energy to increase its pressure. This process is usually accompanied by an increase in temperature, but because LPG is extremely easy to liquefy, its compression process requires special attention to temperature control to prevent liquefaction in the compression chamber, affecting equipment performance and even causing safety problems. In the design of LPG compressors, the following characteristics of LPG must be fully considered:

Flammability and explosiveness: After LPG is mixed with air, it will explode when it encounters a fire source within a certain concentration range.

Corrosiveness: Some LPG may contain trace amounts of sulfides or other impurities, which are corrosive to certain metal materials.

Easy to liquefy: Low boiling point and critical temperature make LPG more likely to undergo phase change during compression.

Density: The density of liquid LPG is much greater than that of gas, and its vapor density is heavier than that of air, and it is easy to accumulate in low-lying areas.

Therefore, LPG compressors will be more stringent in terms of structure and material selection, especially focusing on sealing and explosion-proof performance.

Natural gas compressor:

Natural gas is a combustible natural gas mineral resource that exists in the porous space of underground rocks and is one of the important fossil fuels. Its main component is methane (CH4), which usually accounts for more than 85% to 99% of the total. In addition, it contains a small amount of heavy hydrocarbons such as ethane, propane, butane, and non-hydrocarbon gases such as nitrogen (N2), carbon dioxide (CO2), hydrogen sulfide (H2S) and water vapor. Natural gas exists in gaseous state at normal temperature and pressure, and its liquefaction requires extremely low temperature (methane boiling point is about -162°C) or extremely high pressure. Natural gas compressor (Natural Gas Compressor) is a mechanical equipment specially used to increase the pressure of natural gas to meet specific process or transportation requirements.

The application range of natural gas compressors is extremely wide, and its design is also diverse due to different application scenarios. For example, pipeline compressors used for long-distance transportation need to provide extremely high pressure ratios and flow rates; compressors used in liquefied natural gas (LNG) plants need to operate stably in low-temperature environments and compress natural gas to the pressure required for liquefaction; and compressors used in CNG filling stations are required to compress natural gas to extremely high storage pressures (usually 20-25 MPa).

When designing a natural gas compressor, the following characteristics of natural gas must be considered:

The main component is methane: methane is the simplest hydrocarbon, and its physical and chemical properties are relatively stable, but it is still flammable.

Explosion limit: After natural gas is mixed with air, it can explode when it encounters a fire source within a certain concentration range (usually 5%-15%).

Cryogenic liquefaction characteristics: extremely low temperatures are required for liquefaction, which puts forward special cryogenic materials and insulation requirements for LNG-related applications.

Impurities: Some natural gas may contain corrosive gases such as hydrogen sulfide, and corrosion-resistant materials need to be selected.

Compared with LPG compressors, the stability, reliability and efficiency of natural gas compressors under high pressure, large flow and complex working conditions are often more core considerations.

LPG compressor vs natural gas compressor: main differences

Although both perform the basic function of compressing gas, the essential differences between LPG and natural gas determine that the two compressors are significantly different in many key aspects.

The impact of differences in medium characteristics on design:

LPG: Its most prominent feature is “easy liquefaction”. This means that during the compression process, even a slight temperature rise or pressure fluctuation may cause some gaseous LPG to be converted into liquid. It is extremely dangerous for liquid LPG to enter the working chamber of the compressor, which may cause “hydraulic shock” and seriously damage the valve plate, piston and even the crankshaft. Therefore, the design of LPG compressors places special emphasis on:

Strict temperature control: Equipped with an efficient cooling system, such as a water jacket and an oil cooler, to ensure that the compression chamber temperature is above the LPG dew point.

Measures to prevent liquid shock: such as setting a gas-liquid separator on the suction line, or using specially designed valves to deal with small amounts of liquid LPG.

Extremely high sealing requirements: Since LPG is permeable and leakage will cause serious safety hazards, oil-free lubrication design (such as diaphragm compressors, whose compression chamber is completely isolated from the crankcase) is usually adopted, or advanced non-contact dry gas seals, multi-stage mechanical seals (such as double-end mechanical seals, and with a balancing system) are used to ensure almost zero leakage. Oil-lubricated piston machines may introduce special piston ring and packing seal designs to reduce the contact between LPG and lubricating oil.

Natural gas: Natural gas, which is mainly methane, is relatively “difficult to liquefy”, which means that the risk of liquid hammer during conventional compression is much lower than that of LPG. Therefore, natural gas compressors focus more on:

High-pressure and high-flow capacity: Especially gas pipeline compressors, which need to withstand extremely high pressures and handle huge flows.

Efficiency and reliability: Long-distance pipeline compressors usually need to operate continuously for several years, and have extremely high requirements for efficiency and reliability.

Impurity tolerance: Natural gas may contain impurities such as water, hydrogen sulfide, and carbon dioxide. The compressor needs to have a certain impurity handling capacity or supporting pre-treatment equipment.

Cryogenic application (LNG): In LNG liquefaction plants, compressors need to operate stably in extremely low temperature environments, which requires that all parts in contact with the medium must be made of special alloy materials with low temperature resistance and high toughness, and equipped with special insulation design.

Structure and material selection:

Compressor type: Commonly used are diaphragm, oil-free piston and liquid ring compressors. Diaphragm compressors are widely used in LPG recovery and high-purity LPG compression due to their leakage-free characteristics. The oil-free piston type achieves oil-free operation through special piston rings and packing seals.

Sealing system: It is one of the core technologies. Double-layer or multi-layer mechanical seals are usually used, and a sealing liquid circulation system is equipped to ensure that the medium is completely isolated from the outside world. For piston machines, the design of piston rings and stuffing boxes is particularly critical, and they are often made of polytetrafluoroethylene (PTFE) or special engineering plastics.

Material: Considering that LPG may contain corrosive components, parts in contact with LPG (such as gas valves, piston rods, cylinder liners) are often made of stainless steel, special alloy steel or other corrosion-resistant materials.

Compressor types: There are many types, including reciprocating (piston), centrifugal, screw, etc. Large centrifugal compressors are commonly used in long-distance pipelines, and reciprocating or screw types are commonly used in industry and gas stations.

Sealing system: Most natural gas compressors use oil lubrication systems, but dry gas sealing technology is also used for high pressure or strict occasions.

Material: Generally cast iron, carbon steel or alloy steel is used. For “sour gas” containing hydrogen sulfide, sulfur corrosion-resistant materials such as high nickel alloys are required. For LNG compressors, low-temperature components need to use ultra-low temperature materials such as austenitic stainless steel and nickel alloys.

Safety protection:

LPG compressor: The safety protection level is extremely high.

Explosion-proof level: All LPG-related equipment, including the compressor body, motor, instrumentation, valves, etc., must meet the corresponding explosion-proof level (such as Ex d IIB T4 or Ex d IIC T4) to prevent electrical sparks from igniting LPG steam.

Leak detection: A highly sensitive LPG gas leak detection alarm system is mandatory, and it will automatically shut down or alarm when a leak is detected.

Emergency shut-off and unloading: A complete emergency shut-off valve (ESD) and automatic unloading system ensure that the LPG source is quickly cut off and the system pressure is reduced in an emergency.

Inert gas purge: Before starting or shutting down, it may be necessary to purge the system with inert gases such as nitrogen to discharge residual LPG steam.

Grounding and static protection: Strict grounding measures to prevent static electricity accumulation from causing sparks.

Natural gas compressor:

Explosion-proof level: Explosion-proof design is also required, but according to the characteristics of natural gas methane, the explosion-proof level may be slightly different, but equally strict.

Overpressure protection: Pressure relief valve (PSV), bursting disc and other overpressure protection devices are standard to prevent the system pressure from being too high.

Fire and gas detection: Equipped with combustible gas detectors and flame detectors.

Vibration monitoring and fault diagnosis: Large natural gas compressors are usually equipped with advanced vibration monitoring and online fault diagnosis systems to detect potential problems in advance.

Compression ratio and exhaust pressure:

LPG compressor: Usually in the LPG recovery and filling links, its intake pressure may be low, and the exhaust pressure is usually in the medium range (such as 0.5 MPa to 2.5 MPa) to achieve LPG liquefaction or transportation. Single-stage or two-stage compression can meet most needs.

Natural gas compressor: The pressure range spans a large range.

Long-distance pipelines: The intake pressure may be several MPa, and the exhaust pressure can reach more than ten or even dozens of MPa to overcome the resistance of long-distance pipeline transportation. Multi-stage compression is usually required.

CNG filling station: compressing natural gas from pipeline pressure (usually 0.1-0.4 MPa) to 20-25 MPa requires multi-stage high-pressure compression.

LNG plant: natural gas needs to be compressed to a higher pressure to prepare for subsequent deep-cold liquefaction.

Application scenarios of LPG compressors and natural gas compressors

These two compressors each occupy an irreplaceable position in the energy industry chain.

Main application scenarios of LPG compressors:

LPG filling stations and distribution systems: This is the core application of LPG compressors. It is used to efficiently transfer liquid LPG (or gaseous LPG) from large LPG storage tanks to small gas cylinders, tank trucks, shipping tanks, or unload from transportation vehicles to storage facilities. Through compression, the evaporation loss of liquid LPG can be reduced and the filling or unloading process can be accelerated.

LPG vehicle filling station: At the LPG vehicle filling station, the compressor is responsible for extracting LPG vapor from the storage tank, pressurizing it and sending it to the LPG pump to fill the car with liquid LPG. It can also recover a small amount of gaseous LPG produced during the filling process to improve the efficiency and safety of filling.

LPG recovery in refineries and chemical plants: In the chemical production process such as petroleum refining and ethylene cracking, LPG is produced as a by-product, or LPG tail gas is produced during equipment maintenance and cleaning. LPG compressors can effectively recycle these valuable LPG, reduce environmental emissions, and improve resource utilization. These recycled LPG can be re-entered into the production cycle or sold as fuel.

LPG gasification station: For some industrial or civilian users, LPG needs to be gasified before use. LPG gasification stations usually use compressors to extract liquid LPG from storage tanks, convert it into gas through a gasifier, and then deliver it to users after being pressurized by the compressor to ensure stable gas supply pressure.

Chemical production raw material transportation: In some chemical production lines that use LPG as raw material, LPG compressors are used to pressurize LPG to the pressure required for the reaction.

Main application scenarios of natural gas compressors:

Natural gas long-distance pipeline compression station: Natural gas will reduce pressure due to friction and pressure loss during long-distance pipeline transportation. The compression stations set up along the line are equipped with large natural gas compressors to regularly pressurize natural gas to maintain stable flow and pressure in the pipeline, ensuring that natural gas is efficiently and economically delivered to all parts of the country.

Liquefied Natural Gas (LNG) Plant: LNG is a product of natural gas that has been deeply cooled (-162°C) and liquefied. Its volume is greatly reduced, making it easier to transport and store by sea. In an LNG plant, the natural gas compressor is one of the core equipment, used to compress natural gas to the pressure required for the liquefaction cycle. This usually involves a complex refrigeration cycle, requiring an efficient and reliable multi-stage compressor unit.

Compressed Natural Gas (CNG) Filling Station: CNG is natural gas compressed to a high pressure of 20-25 MPa at room temperature, stored in high-pressure gas cylinders, and used as automobile fuel. The natural gas compressor at the CNG filling station is a high-pressure multi-stage reciprocating compressor, which is responsible for pressurizing the low-pressure natural gas in the pipeline network to the CNG storage pressure.

Natural Gas Processing Plant and Purification Station: Natural gas extracted from gas fields usually contains impurities such as hydrogen sulfide, carbon dioxide, and water vapor. Before entering the long-distance pipeline, it needs to be purified by desulfurization, decarbonization, and dehydration. Natural gas compressors are used to increase the pressure of natural gas in these processing links to ensure the smooth progress of the processing process.

Gas Power Plant: Large gas turbines require high-pressure natural gas as fuel for power generation. Natural gas compressors are responsible for boosting the natural gas entering the power plant to the combustion pressure required by the gas turbine.

Oil and gas field gathering and boosting: In the early stages of oil and gas field exploitation, the natural gas may be at a high pressure, but as exploitation progresses, the wellhead pressure will drop. Natural gas compressors are used to boost the low-pressure wellhead gas so that it can enter the gathering and transportation network or be further processed. At the same time, the recovery and utilization of associated natural gas also cannot be separated from compressors.

Industrial and commercial gas supply: In industries such as ceramics, glass, steel, and chemicals, natural gas is widely used as a fuel or chemical raw material as a clean energy. Natural gas compressors ensure that these industrial users receive a stable and sufficient pressure gas supply.

Key factors when selecting LPG compressors and natural gas compressors

The correct selection of compressors is the basis for ensuring efficient, safe, and economical operation of the system. The following are key factors that need to be considered comprehensively:

Physical and chemical properties of the treatment medium:

Component analysis: A detailed understanding of the propane and butane ratios in LPG, or the methane content and impurity content such as H2S and CO2 in natural gas. This directly determines the anti-corrosion requirements, sealing material selection, and safety level of the compressor.

Temperature and pressure range: Specify the minimum/maximum temperature and pressure of the inlet gas, as well as the required outlet pressure. These parameters determine the number of compressor stages, power, and cooling system design.

Dew point/critical parameters: Especially for LPG, pay attention to its dew point temperature to ensure that liquefaction does not occur during the compression process.

Flow and displacement requirements:

Maximum/minimum flow: According to process requirements, determine the maximum and minimum processing capacity of the compressor under different working conditions, and select a compressor with appropriate displacement and adjustment range.

Continuous operation: If 24/7 continuous operation is required, the reliability and stability of the equipment are extremely high, and a heavy-duty industrial compressor should be selected.

Energy efficiency and operating cost:

Specific power: An important indicator for measuring compressor efficiency. Choosing a compressor with a lower specific power means consuming less electricity or fuel at the same flow and pressure.

Energy consumption cost: Compressors are high-energy consuming equipment, and the electricity or fuel costs for long-term operation are the main operating costs. Therefore, high-efficiency compressors can bring significant economic benefits.

Maintenance cost: Consider the life of the equipment’s wearing parts, maintenance cycle, and spare parts price. Choose equipment that is easy to maintain, has readily available spare parts and is reasonably priced.

Safety and Compliance:

Explosion-proof grade certification: It must comply with local or international explosion-proof standards (such as ATEX, IECEx, GB, etc.) to ensure the explosion-proof performance of electrical equipment and mechanical components.

Safety protection system: Ensure that the compressor is equipped with complete protection devices such as overpressure, overtemperature, low oil pressure, high vibration, and emergency stop buttons.

Leakage control: Especially for LPG compressors, reliable sealing and leakage detection alarm systems must be available.

Fire and anti-static: Take necessary fire prevention measures and strict grounding measures to prevent static electricity accumulation.

Reliability and life:

Brand reputation and experience: Choose a manufacturer with rich experience and good reputation in the field of LPG or natural gas compression.

Operation history: Understand the operation history and failure rate of the target equipment under similar working conditions.

Quality of key components: Pay attention to the materials and suppliers of key components such as valve plates, piston rings, bearings, and seals.

Installation space, environmental conditions and noise:

Floor space and height: Consider the installation space restrictions on site.

Ambient temperature and humidity: The compressor should be able to operate stably under local extreme climatic conditions.

Noise and vibration: Especially for places close to residential areas or with strict noise requirements, low-noise design or the installation of soundproof covers should be considered.

Altitude: The air density is low in high altitude areas, and special design of the compressor or the selection of a higher-power motor may be required.

Automation and control system:

Control accuracy: Whether precise flow or pressure control is required.

Remote monitoring and fault diagnosis: Modern compressors are usually equipped with PLC or DCS control systems, which support remote monitoring, data acquisition, trend analysis and fault warning to improve operation and maintenance efficiency.

Interlock protection: The interlock protection function with upstream and downstream equipment ensures the coordinated operation of the entire system.

Supplier technical support and after-sales service:

Technical consultation: Whether the supplier can provide professional technical consultation and selection suggestions.

Installation and commissioning: Whether professional installation guidance and on-site commissioning services are provided.

Spare parts supply: Ensure the timeliness and reliability of long-term spare parts supply.

Maintenance training: Whether professional training for operators and maintenance personnel is provided.

Conclusion

Although LPG compressors and natural gas compressors are both gas compression equipment at the macro level, they show distinct differences in micro engineering design and application practice. These differences are not accidental, but are determined by the unique physical and chemical properties of LPG and natural gas they process. The liquefaction and flammability and explosion of LPG have prompted LPG compressors to meet extremely high standards in terms of sealing, explosion protection and liquid impact protection; while the diverse application scenarios of natural gas (from long-distance pipelines to LNG liquefaction) require natural gas compressors to have excellent performance in high pressure, large flow, extreme low temperature and high efficiency.

Correctly understanding and distinguishing the core characteristics of these two compressors and their respective application fields is crucial for engineers and decision makers in the energy, petrochemical, chemical, transportation and other industries. In the process of equipment selection, it is necessary to take a rigorous attitude and comprehensively consider multiple factors such as medium characteristics, process requirements, safety standards, operating costs and environmental impacts to ensure that the selected compressor can not only meet current production needs, but also operate safely, efficiently and economically for a long time. As the global demand for clean energy continues to grow and related technologies continue to advance, both LPG compressors and natural gas compressors will continue to develop in a more environmentally friendly, smarter and more efficient direction, contributing to building a sustainable energy future.