Revolutionize your hydrogen journey with a Hydrogen Compressor — where innovation meets efficiency. Our cutting-edge technology ensures optimal compression, delivering sustainable and intelligent solutions. Safety is our priority. Explore the future of clean energy.

Leading Hydrogen Compressor Manufacturer

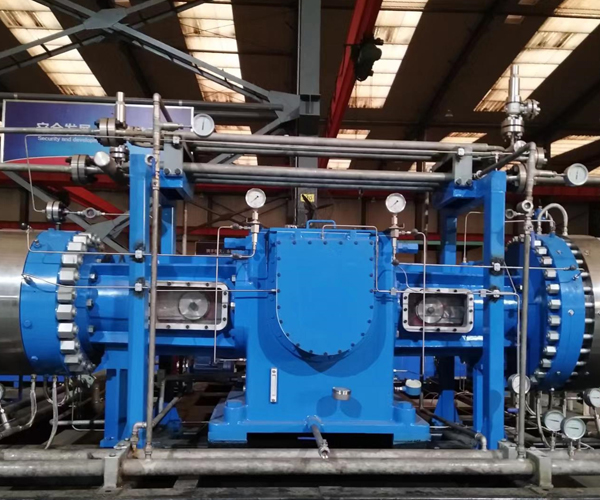

Sollant has rich design and manufacturing experience, professional and powerful production and processing capabilities in forging, casting, heat treatment, welding, machining, assembly testing, etc., as well as complete technical testing equipment and means, which can conduct product testing according to the user’s usage conditions. With its deformed design, manufacturing and installation, it has now reached an annual production capacity of 500 gas compressors of various types. Currently, the compressors produced by the company have exhaust pressures up to 50MPa. Its products cover national defense, aerospace, nuclear power, energy, Petrochemicals and other fields.

Features

- Good sealing performance: Diaphragm compressor is a special structure positive displacement compressor. The gas does not need lubrication and has good sealing performance. The compressed medium does not come into contact with any lubricant and does not produce any pollution during the compression process. It is especially suitable for high purity (99.9999 % or more), compression, transportation and filling of precious and rare, extremely corrosive, toxic and harmful, flammable and explosive, radioactive gases.

- The cylinder has good heat dissipation performance: The working cylinder of the diaphragm compressor has good heat dissipation performance and is close to isothermal compression. It can use a higher compression ratio and is suitable for compressing high-pressure gas.

Technical Advantages

- The diaphragm compressor has low rotation speed and extends the service life of wearing parts. The new membrane cavity curve improves the volumetric efficiency of the compressor and optimizes the valve adjustment. The diaphragm adopts a special heat treatment method, which greatly improves the service life.

- The use of a high-efficiency cooler ensures low temperature and high efficiency of the entire machine, which can appropriately extend the life of lubricating oil, O-rings, and valve springs. Under the condition that the process parameters are met, the structure is more advanced, reasonable and energy-saving.

- The membrane head is sealed with inlaid double O-rings, and its sealing effect is far better than that of the open membrane head.

- The diaphragm rupture alarm structure is advanced, reasonable and reliable. The diaphragm has no direction when installed and is easy to replace.

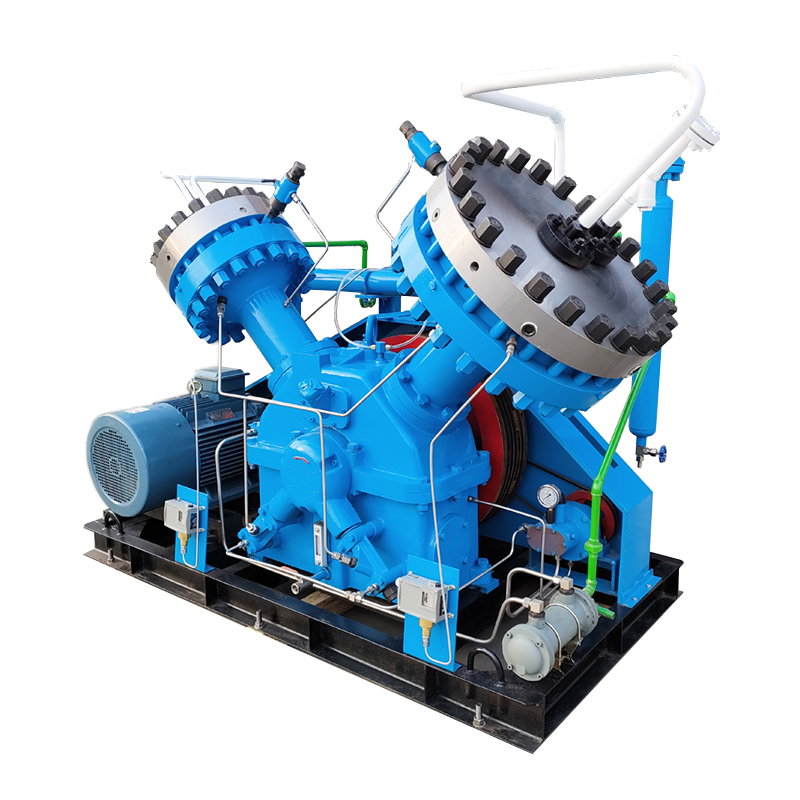

Structural form: V Type

Piston stroke: 70mm~130mm

Maximum piston force: 10KN~30KN

Maximum exhaust pressure: 50MPa

Flow range: 2~200Nm³/h

Motor power: 2.2KW~30KW

Crankshaft speed: 420rpm

Cooling method: water cooling/air cooling (optional)

Structural form: Z type

Piston stroke: 70mm~180mm

Maximum piston force: 10KN~90KN

Maximum exhaust pressure: 70MPa

Flow range: 0.5~500Nm³/h

Motor power: 2.2KW~55KW

Crankshaft speed: 420rpm

Cooling method: water cooling/air cooling (optional)

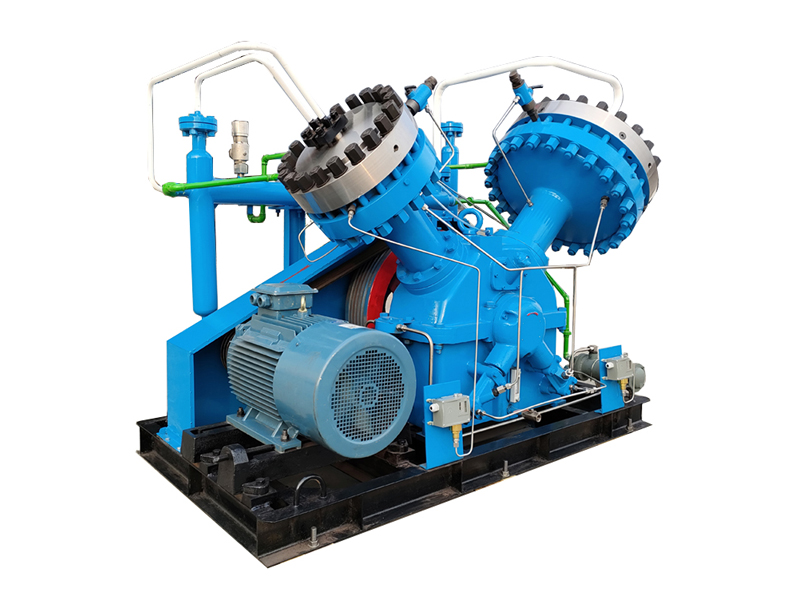

Structural form: L Type

Piston stroke: 110mm~180mm

Maximum piston force: 20KN~40KN

Maximum exhaust pressure: 100MPa

Flow range: 10~1000Nm³/h

Motor power: 7.5KW~90KW

Crankshaft speed: 420rpm

Cooling method: water cooling/air cooling (optional)

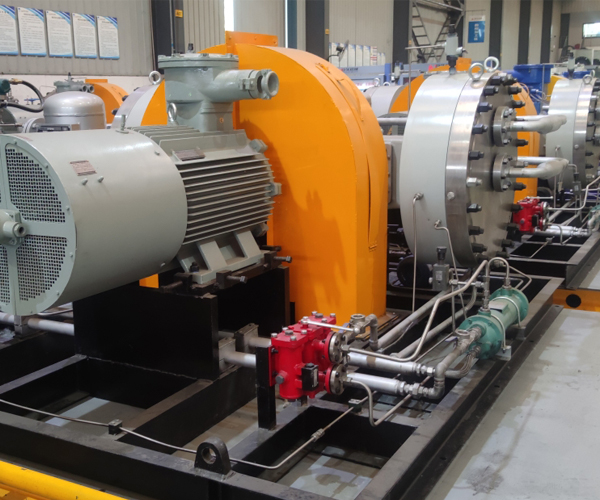

Structural form: D type, symmetrically balanced type

Piston stroke: 130mm~210mm

Maximum piston force: 40KN~160KN

Maximum exhaust pressure: 100MPa

Flow range: 30~2000Nm³/h

Motor power: 22KW~200KW

Crankshaft speed: 420rpm

Cooling method: water cooling/air cooling (optional)

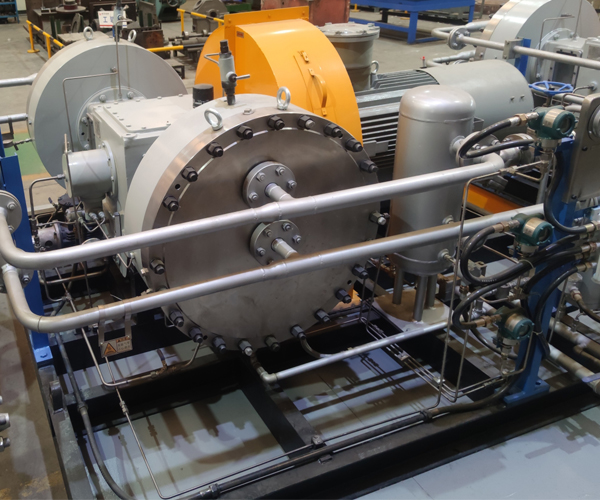

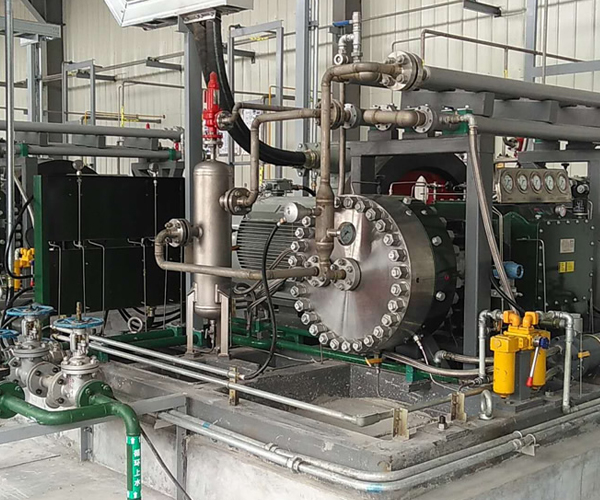

Case Project

Reach Out for Inquiries & Technical Support

For inquiries about our process gas compressors, custom solutions, or technical support, please fill out the form below or contact us directly.