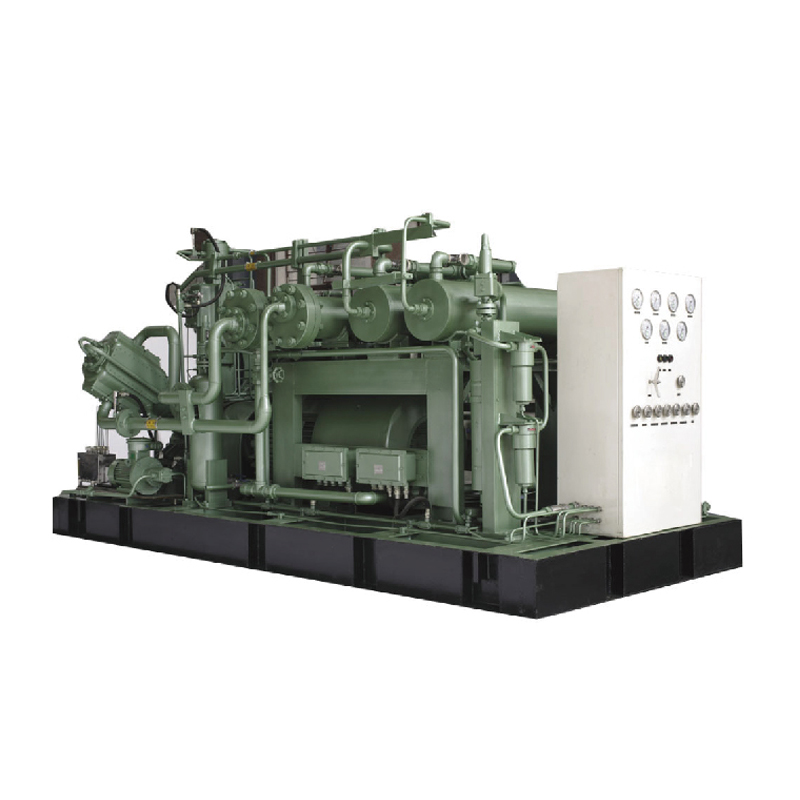

CNG Standard Station Compressor

Equipment composition: air inlet filter pressure regulating metering device, desulfurization tower, low-pressure dehydration device, piston compressor, sequence control panel, gas storage bottle group, gas dispenser, gas column, CNG trailer, gas alarm device and other equipment.

Covered area: about 2000~4000m2

Optimal transportation radius: 150km

Suitable scale: 240000Nm3/d

Equipment installation time: about 30 days.

CNG standard stations are built where natural gas pipelines pass by and draw gas directly from the natural gas pipelines. The natural gas enters the compressor unit through desulfurization, pressure regulation, metering, filtration, dehydration and other processes, and then is compressed, cooled and purified to increase the pressure to 25Mpa. Finally, the high-pressure trailer is refueled through the gas filling column and also through the gas vending machine. Add gas to your car. Our company can provide complete solutions and turnkey projects.

Here are key features and functions associated with a CNG Standard Station Compressor:

- Gas Compression: The primary function of the compressor is to elevate the pressure of natural gas to the required level for vehicle refueling. This compression process is essential for making natural gas a viable and efficient alternative fuel.

- High-Pressure Output: CNG is stored and dispensed at high pressures, typically measured in pounds per square inch (psi) or bar. The compressor ensures that the gas reaches the necessary pressure level for safe and effective refueling.

- Safety Features: Compressing natural gas involves dealing with high-pressure systems, and safety is a paramount concern. CNG Standard Station Compressors incorporate various safety features to prevent over-pressurization, leaks, and other potential hazards.

- Dispensing Integration: The compressor is integrated with the dispensing unit at the station. Once the natural gas is compressed, it is ready for dispensing into vehicles. The compressor works in tandem with the dispenser to ensure a controlled and safe refueling process.

- Regulatory Compliance: Compressors at CNG stations adhere to industry and safety standards and comply with local regulations. Compliance is crucial to ensuring the safe operation of the station and the reliability of the compressed natural gas provided.

- Monitoring and Control Systems: Modern CNG Standard Station Compressors often feature advanced monitoring and control systems. These systems allow operators to track and manage the compressor’s performance, monitor pressure levels, and ensure optimal efficiency.

Gas Filling Station Flow Chart

Technical Parameters and Specifications

| No. | Model | Intake pressure(Mpa) | Air supply (Nm³/h) | Power (KW) | Cooling | Weight (T) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| 1 | W-5.6/0.5-250 | 0.05 | 500 | 160 | Water | 9 | 5000×2300×2200 |

| 2 | W-3.6/1-250 | 0.1 | 435 | 110 | Water | 6 | 2400×2220×2150 |

| 3 | W-4.75/1-250 | 570 | 132 | Water | 6 | 2400×2220×2150 | |

| 4 | W-7.5/1-250 | 900 | 270 | Water | 17 | 8500×2260×2200 | |

| 5 | W-4.5/1.4-250 | 0.14 | 650 | 160 | Water | 7 | 3820×2270×2150 |

| 6 | W-4.7/2-250 | 0.2 | 850 | 185 | Water | 7 | 3820×2270×2150 |

| 7 | WF-3.6/(1.5~2.5)-250 | 0.15~0.25 | 540~750 | 160 | Air | 14 | 6200×2190×2080 |

| 8 | W-3.6/(1.5~3)-250 | 0.15~0.3 | 540~860 | 185 | Water | 7 | 4000×2270×2150 |

| 9 | V-3.2/(3-5)-250 | 0.3~0.5 | 760-1150 | 220 | Air | 14 | 6300×2525×2500 |

| 10 | VF-3.2/(3~5)-250 | 770~1150 | 220 | Air | 14 | 6300×2500×2500 | |

| 11 | W-1.5/8-250 | 0.8 | 810 | 132 | Water | 8 | 4000×2300×2000 |

| 12 | VF-2/(10~16)-250 | 1.0~1.6 | 1320~2000 | 280 | Air | 10 | 5600×2500×2300 |

| 13 | D-5/(2~4)-250 | 0.2~0.4 | 900~1500 | 315 | Water、Air | 23 | 5000×3500×2500 |

| 14 | D-4.2/(3~6)-250 | 0.3~0.6 | 1000-1760 | 280 | Water、Air | 23 | 5000×3500×2500 |

| 15 | D-3.6/(4~7)-250 | 0.4~0.7 | 1050~1730 | 315 | Water、Air | 23 | 5000×3500×2500 |

| 16 | D-2.6/(7~12)-250 | 0.7~1.2 | 1250~2000 | 280 | Water、Air | 20 | 5000×3500×2500 |

| 17 | VF-0.76/(7~13)-250 | 0.7~1.3 | 365~640 | 100 | Air | 8 | 6000×2200×2230 |

Reach Out for Inquiries & Technical Support

For inquiries about our process gas compressors, custom solutions, or technical support, please fill out the form below or contact us directly.