Application and Challenges of Hydrogen Compressors in the Field of Clean Energy

Under the current dual pressures of global climate change and energy transformation, finding and developing clean and sustainable energy has become a general consensus of the international community. Hydrogen energy, with its unique advantages such as high energy density, zero emissions, and diverse sources, is known as the “ultimate energy” of the 21st century and is gradually becoming the focus of energy strategic layout of various countries. The acquisition, storage, transportation and utilization of hydrogen constitute a complex hydrogen energy industry chain, and in this industry chain, hydrogen compressors play a vital role. It is like a heart, providing power for the circulation and effective utilization of hydrogen. Whether it is pressurizing the hydrogen produced by low-pressure electrolysis of water for easy storage, or accurately filling the hydrogen stored in the hydrogen storage tank into a fuel cell vehicle, or providing a stable and high-pressure hydrogen source for industrial production, hydrogen compressors are indispensable. The quality of its performance, efficiency and reliability directly determine the economy, safety and speed of popularization of hydrogen energy. This article will explore the broad application prospects of hydrogen compressors in the field of clean energy, the significant advantages they bring, the latest progress of current technological innovation, and frankly analyze the challenges they face in the process of promotion and application, in order to provide a theoretical basis and practical reference for promoting the healthy development of the hydrogen energy industry.

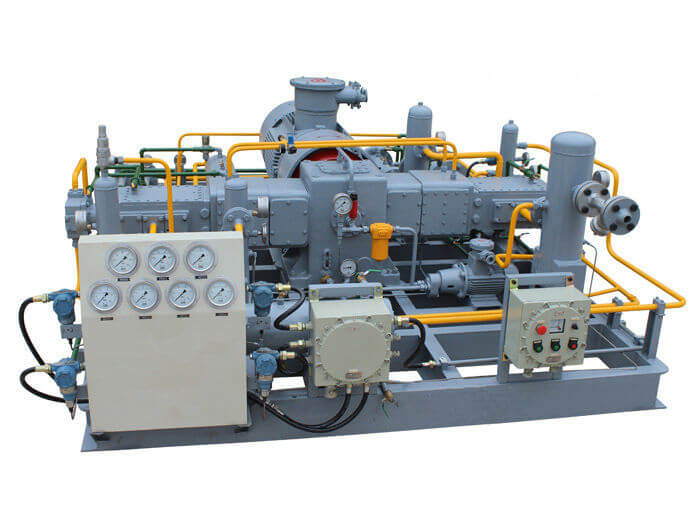

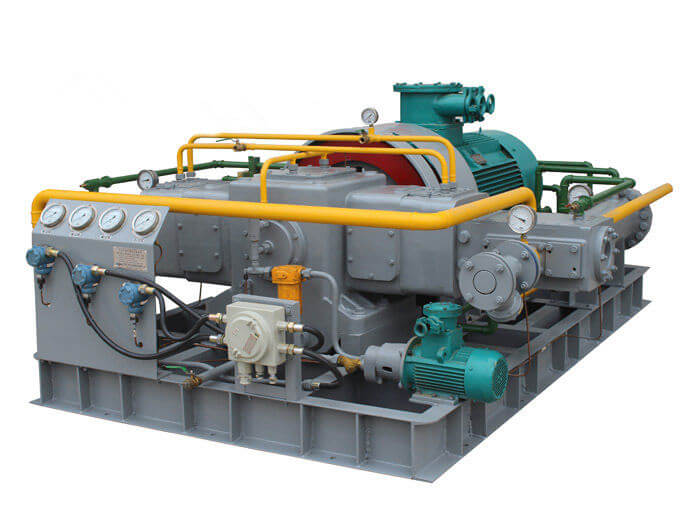

Overview of Hydrogen Compressors

Hydrogen compressors are mechanical equipment that raises low-pressure hydrogen to a high-pressure state. Their working principle is based on the basic law of gas compression, that is, reducing the volume of the gas through mechanical energy input to increase its pressure. Due to the unique physical and chemical properties of hydrogen – extremely small molecules, easy leakage, flammable and explosive, hydrogen embrittlement effect on certain metals, and the need for extremely high purity, the design, material selection, sealing technology and safety protection of hydrogen compressors are much more stringent than those of ordinary gas compressors.

According to their working principles and structural characteristics, hydrogen compressors can be subdivided into the following main types:

Piston hydrogen compressors:

Working principle: Piston compressors are one of the most widely used and most mature types of compressors. Its core working component is the reciprocating motion of the piston in the cylinder. When the piston moves downward, the suction valve opens and low-pressure hydrogen is sucked into the cylinder; when the piston moves upward, the suction valve closes, the exhaust valve opens, and the hydrogen is compressed and discharged through the exhaust valve. Through multi-stage series connection, a very high compression ratio can be achieved.

Advantages: Piston compressors usually have a high compression ratio and efficiency, can achieve a wide range of pressures from low pressure to ultra-high pressure (such as 20MPa to 90MPa or even higher), have a large flow adjustment range, and are highly adaptable. Its structure is relatively simple, easy to manufacture and maintain.

Disadvantages: The reciprocating motion of the piston causes large mechanical vibration and noise. More importantly, traditional piston compressors require lubricating oil to reduce the friction between the piston and the cylinder wall, but the lubricating oil will inevitably come into contact with hydrogen, thereby introducing oil vapor impurities and reducing the purity of hydrogen, which is a fatal defect for applications such as fuel cells that require extremely high hydrogen purity. In addition, frequent wear of moving parts will also increase maintenance frequency and cost.

Development and improvement: In order to solve the problem of oil pollution, oil-free lubricated piston compressors (such as those using polytetrafluoroethylene or carbon fiber composite piston rings) and dry piston compressors have gradually been used, but their reliability and life still need to be improved.

Diaphragm hydrogen compressor:

Working principle: The diaphragm compressor uses a flexible diaphragm as a piston to completely isolate the hydrogen from the lubricating oil in the crankcase. When the hydraulic oil (usually oil or water) in the crankcase pushes the diaphragm to move, the diaphragm will compress the hydrogen on the other side. This design fundamentally avoids the contact between hydrogen and lubricants, thereby ensuring 100% purity of hydrogen and achieving the effect of oil-free compression.

Advantages: The biggest advantage is that it can provide extremely pure hydrogen without oil pollution, which is crucial for fuel cells, semiconductor manufacturing, food industry and other fields with strict requirements on gas purity. Secondly, it has good sealing, low leakage rate and high safety.

Disadvantages: The material of the diaphragm (such as stainless steel, Hastelloy, polyimide, etc.) needs to have extremely high fatigue strength, corrosion resistance and elasticity. It is easy to fatigue damage under high pressure and high frequency movement, resulting in a relatively short diaphragm life. The single-stage compression ratio is usually low, and multiple stages are required in series to achieve high pressure, which increases the complexity and cost of the equipment. The flow rate is relatively small and is not suitable for large flow applications.

Application: Widely used in pre-compression of hydrogen refueling stations, fuel cell test platforms, hydrogen fuel cell forklifts, and industrial gas purification.

Ionic liquid compressor:

Working principle: The ionic liquid compressor is a relatively new technology that uses room temperature ionic liquid as a “liquid piston” or sealing medium to compress hydrogen. Ionic liquids are a class of salts composed of anions and cations that are liquid at room temperature. They have excellent properties such as extremely low vapor pressure, non-flammable, non-toxic, and low solubility in hydrogen. During the compression process, the ionic liquid is in direct contact with the hydrogen, achieving compression through its movement, while providing sealing and cooling.

Advantages: Theoretically, 100% oil-free compression can be achieved, and there is almost no gas leakage because the ionic liquid is self-sealing. Its low vapor pressure means that no vapor impurities will be introduced. In addition, ionic liquids have good thermal conductivity, which helps to remove heat during the compression process.

Disadvantages: Ionic liquids are expensive and have relatively high viscosity, which increases pumping power consumption. This technology is still in the research and development and demonstration stage, and commercial applications have not yet been popularized. There are great engineering challenges, including compatibility of ionic liquids with materials, long-term stability, and recycling.

Development prospects: It is considered to be an important direction for ultra-high pressure and high purity hydrogen compression in the future, especially for scenes such as hydrogen refueling stations that require high pressure and oil-free hydrogen.

Liquid metal piston compressor:

Working principle: This innovative technology also uses liquid media as pistons, but uses low melting point liquid metals (such as gallium-based alloys or bismuth-based alloys). Liquid metal has excellent thermal conductivity and electrical conductivity, and remains liquid at a certain temperature. The reciprocating motion of liquid metal is driven by an electromagnetic pump or a mechanical pump to achieve compression of hydrogen. Liquid metal does not react chemically with hydrogen, which can effectively avoid hydrogen embrittlement and contamination.

Advantages: It can achieve completely oil-free, friction-free, and mechanical wear-free compression, and theoretically can achieve extremely high compression ratios and high purity. The good thermal conductivity of liquid metal helps to effectively dissipate heat and improve isothermal compression efficiency.

Disadvantages: Liquid metal is expensive and needs to maintain a certain temperature to keep it in liquid state, which increases energy consumption. The technology is still in the laboratory research stage, and the engineering implementation is difficult, including the cycle stability of liquid metal, sealing technology, and material corrosion.

Development prospects: In the long run, it is expected to become a disruptive technology for the next generation of ultra-high pressure, high efficiency, and high reliability hydrogen compressors.

Scroll hydrogen compressor:

Working principle: The scroll compressor consists of two intermeshing scroll disks, one of which is fixed and the other rotates or swings eccentrically. Hydrogen is sucked into the crescent-shaped cavity formed by the two scroll disks. As the scroll disks move relative to each other, the cavity volume gradually decreases, thereby achieving continuous compression of hydrogen.

Advantages: Compact structure, small size, light weight, low vibration, and low noise. Since there are no reciprocating parts, it has low wear and long life. Usually adopt oil-free lubrication design, which can provide higher purity hydrogen.

Disadvantages: The compression ratio is relatively low, and it is usually suitable for medium and low pressure applications (such as below 10 MPa). The flow range is also relatively limited.

Application: It is suitable for small hydrogen refueling stations, hydrogen fuel cell backup power supplies, hydrogen circulation systems and other fields.

Metal hydride compressor:

Working principle: This is a “solid compression” technology based on the principle of thermodynamics. Some metals or alloys (such as LaNi5, AB2 type alloys, etc.) release heat when absorbing hydrogen to form metal hydrides, and release hydrogen when the temperature is increased or the pressure is reduced. By precisely controlling the temperature and pressure and utilizing the hydrogen absorption and desorption characteristics of metal hydrides, the “adsorption-desorption” cycle of hydrogen can be realized, thereby achieving the purpose of compressing hydrogen.

Advantages: No mechanical moving parts, quiet operation, and almost no vibration. Relatively low energy consumption, mainly input in the form of heat energy. It can achieve very high hydrogen purity and can also purify hydrogen at the same time.

Disadvantages: The compression cycle is long, resulting in a slow compression rate, which is not suitable for large flow continuous compression. The start and stop response speed is slow. The hydrogen absorption and desorption capacity is limited by the material properties, and the material cost is high.

Application: Mainly used in small-scale hydrogen storage, hydrogen purification, and fuel cell testing and research, not suitable for large-scale continuous high-pressure compression.

When choosing a type of hydrogen compressor, it is necessary to comprehensively consider the pressure demand, flow demand, hydrogen purity requirements, cost budget, maintenance convenience, and floor space of the application scenario.

Application of hydrogen compressors in the field of clean energy

Hydrogen compressors play a key role in the entire clean energy industry chain, and their application runs through all aspects of hydrogen production, storage, transportation, filling and utilization.

Hydrogen storage and transportation:

High-pressure gaseous hydrogen storage: Hydrogen has an extremely low volume energy density at room temperature and pressure. In order to store and transport it efficiently, it must be pressurized. High-pressure gaseous hydrogen storage is one of the most mainstream hydrogen storage methods at present. Hydrogen compressors can raise hydrogen from the lower pressure of hydrogen production (such as 0.8MPa for water electrolysis) to the pressure required by high-pressure storage tanks. For example, on-board hydrogen storage tanks are usually 35MPa or 70MPa, while the fixed tank pressure of hydrogen refueling stations can reach 87.5MPa (70MPa for vehicle refueling, with a certain pressure difference reserved) or even higher, and may reach more than 100MPa in the future. Efficient hydrogen compressors make it possible to store large amounts of hydrogen in relatively small containers, which is crucial for hydrogen station construction and the range of hydrogen fuel cell vehicles.

Long-tube trailer transportation: For long-distance transportation of hydrogen, high-pressure long-tube trailers are usually used. The hydrogen compressor is responsible for compressing hydrogen into the long-tube storage tank inside the trailer, such as 20MPa or higher pressure, so as to carry more hydrogen in one transportation, reducing transportation frequency and cost. At the receiving end, compressors are usually also required for unloading and further pressurization.

Hydrogen pipeline transportation: With the development of hydrogen energy infrastructure, more hydrogen transportation pipelines may be built in the future. Pipeline transportation also requires hydrogen compressors (or compression stations) to increase pressure along the way to overcome pipeline resistance and ensure that hydrogen can be efficiently and long-distance transported to end users.

Fuel cell vehicle hydrogen refueling station:

Hydrogen refueling stations are the core hubs of hydrogen energy infrastructure, connecting the supply and demand sides of hydrogen. One of its core equipment is the hydrogen compressor. Hydrogen refueling stations usually receive low-pressure hydrogen from the outside (such as through tube bundle vehicles or pipelines), pressurize hydrogen to the tank pressure (such as 87.5MPa) through compressors, and further pressurize to the refueling pressure required by fuel cell vehicles (such as 35MPa or 70MPa) to achieve fast and efficient refueling.

The performance of the compressor directly affects the refueling speed, refueling volume and operating costs of the hydrogen refueling station. High-performance compressors can complete refueling in a short time, reduce vehicle waiting time, and improve the operating efficiency and profitability of hydrogen refueling stations. For example, to refuel a 70MPa fuel cell vehicle, a hydrogen compressor is required to stably provide hydrogen at a pressure of 70MPa or even higher, and handle the pressure fluctuations caused by the increase in temperature during the refueling process.

Hydrogen fuel cell power generation:

Hydrogen fuel cell power generation systems, whether used for fixed power generation (such as distributed power, backup power) or mobile power generation (such as fuel cell ships, drones), require a stable, high-pressure hydrogen supply. The hydrogen compressor is responsible for extracting hydrogen from the tank or pipeline and pressurizing it to the working pressure required by the fuel cell stack (usually several atmospheres to tens of atmospheres, depending on the type of fuel cell).

In some large fuel cell power plants, a hydrogen circulation compressor may also be required to recompress the unreacted hydrogen from the fuel cell anode outlet and send it back to the inlet to improve the utilization rate of hydrogen. In addition, air compressors also play an important role in fuel cell systems, providing oxygen to the cathode.

Hydrogen supply in the industrial field:

Hydrogen is widely used in many industrial fields such as petrochemicals (hydrocracking, hydrorefining), metallurgy (direct reduction of iron), electronics (reducing atmosphere in semiconductor manufacturing), glass manufacturing, food processing (oil hydrogenation), etc. With the trend of “replacing coal with hydrogen and replacing natural gas with hydrogen”, the amount of industrial hydrogen will continue to grow.

Hydrogen compressors ensure that these industrial users can obtain hydrogen at the required pressure and flow rate to meet their production process requirements. For example, in semiconductor manufacturing, there are extremely high requirements for hydrogen purity, so diaphragm or oil-free piston compressors are usually used.

Renewable energy hydrogen production and consumption:

With the large-scale development of renewable energy such as wind power and solar energy, its intermittent and volatile nature has brought challenges to the power grid. Hydrogen production through water electrolysis is an important way to absorb wind, light and water abandonment and realize the transformation of “green electricity” to “green hydrogen”. Hydrogen production by water electrolysis usually produces hydrogen with low pressure (normal pressure to several megapascals). In order to effectively store, transport or use this “green hydrogen”, it must be pressurized by hydrogen compressors.

The role of hydrogen compressors in this link is to centrally pressurize the dispersed, low-pressure hydrogen so that it can be incorporated into the hydrogen energy infrastructure, thereby opening up the channel from renewable energy to the final application and promoting the deep decarbonization of the energy system.

Circulation and pressurization in hydrogen production plants:

In large-scale hydrogen production plants, no matter which hydrogen production process is used (such as water electrolysis, natural gas reforming, coal gasification, etc.), the produced hydrogen usually needs to be pressurized by a compressor after purification so that it can be transported to storage facilities or directly supplied to end users. At the same time, some process flows in the plant may also require hydrogen circulation compressors to maintain the stable operation of the system and improve the utilization rate of hydrogen.

In summary, hydrogen compressors are the “veins” of the hydrogen energy industry chain. Their efficient, safe and reliable operation is the cornerstone for realizing large-scale commercial application of hydrogen energy and promoting clean energy transformation.

Advantages of hydrogen compressors in clean energy applications

The wide application of hydrogen compressors in the field of clean energy has brought it many significant advantages, which together have promoted the vigorous development of the hydrogen economy:

Increase hydrogen storage density and optimize space utilization:

The density of hydrogen under standard conditions is only 0.08988 kg/m³, and its volume energy density is extremely low (only 1/3 of methane). This means that a huge volume is required to store the same amount of hydrogen at normal pressure. By compressing it to high pressure (such as 35MPa or 70MPa) through a hydrogen compressor, the volume density of hydrogen can be significantly increased by hundreds of times, thereby greatly reducing the volume of the hydrogen storage container. For example, the energy density of 70MPa hydrogen can reach about half of that of liquid hydrogen without the need for ultra-low temperature equipment.

This advantage is crucial for space-constrained application scenarios, such as fuel cell vehicle onboard hydrogen storage tanks, fixed storage tanks at hydrogen refueling stations, and long tube trailers. Higher hydrogen storage density means that fuel cell vehicles can have a longer driving range, hydrogen refueling stations can store more hydrogen to meet peak demand, and long-tube trailers can transport more hydrogen at a time, effectively reducing logistics costs.

Reduce hydrogen transportation costs and improve efficiency:

The transportation cost of uncompressed low-pressure hydrogen is extremely high because the amount of hydrogen transported each time is very limited. By pressurizing hydrogen with a hydrogen compressor, the amount of hydrogen transported at a time can be significantly increased. Whether it is through a high-pressure long-tube trailer or a future hydrogen pipeline, high-pressure transportation can greatly improve transportation efficiency and reduce the transportation cost per unit of hydrogen.

Especially in the early stages of the hydrogen energy industry chain, when pipeline infrastructure is not perfect, high-pressure trailer transportation is the mainstream method. Compressors enable trailers to carry more hydrogen, reduce transportation frequency, and save fuel and labor costs.

Improve hydrogen refueling efficiency and improve user experience:

At hydrogen refueling stations, efficient hydrogen compressors are the key to achieving fast refueling. By pre-compressing hydrogen to a higher pressure (such as 87.5MPa) and cooperating with a fast filling control system, fuel cell vehicles can be filled in a short time (usually within 3-5 minutes), which is comparable to the refueling time of traditional fuel vehicles.

Fast filling greatly improves the user experience of fuel cell vehicles, eliminates range anxiety, makes them more attractive in the competition with traditional fuel vehicles and electric vehicles, and is an important factor in promoting the popularization of fuel cell vehicles.

Ensure efficient and stable operation of fuel cells:

Fuel cell stacks have strict requirements on the pressure and flow of hydrogen supply. Too low or unstable pressure will cause the output power of fuel cells to drop or even shut down. Hydrogen compressors can stably pressurize hydrogen to the working pressure required by fuel cells to ensure that fuel cells operate under optimal conditions.

In addition, some fuel cell systems require hydrogen circulation to recover unreacted hydrogen and re-send it to the stack to improve hydrogen utilization. Hydrogen circulation compressors play an important role in this, ensuring the efficiency and economy of the system.

Expand hydrogen application scenarios and empower multiple fields:

Hydrogen compressors enable hydrogen to be applied to various scenarios at appropriate pressures. For example, high-pressure hydrogen can be used for refining and synthesis in industrial production; medium-pressure hydrogen can be used for distributed fuel cell power generation; low-pressure hydrogen can be used in household fuel cell cogeneration systems after pressurization.

Without a compressor, the use of hydrogen will be greatly limited, and it will be difficult to realize its huge potential as an energy carrier. The compressor breaks the bottleneck of hydrogen in pressure and storage, enabling it to flexibly adapt to various terminal needs, thereby promoting the widespread application of hydrogen in transportation, industry, construction, electricity and other fields.

Promoting the consumption of renewable energy and optimizing the energy structure:

Hydrogen compressors are a key link in the “electricity-hydrogen-X” energy conversion chain. By converting the electricity generated by renewable energy (such as wind power and photovoltaics) into hydrogen through water electrolysis, and then using compressors to pressurize and store it, the intermittent and instability problems of renewable energy can be effectively solved, and “peak shaving and valley filling” can be achieved.

When the grid load is low and the power generation of renewable energy is large, the excess electricity can be used to produce hydrogen and compressed for storage; when the grid load is high and the power generation of renewable energy is insufficient, the stored hydrogen can be used to generate electricity through fuel cells or directly burned to supplement the grid, thereby improving the stability and flexibility of the grid and accelerating the clean transformation of the energy structure.

These advantages together constitute the irreplaceable value of hydrogen compressors in the clean energy system, making it a key technical support for promoting the development of the hydrogen energy industry and achieving the goal of carbon neutrality.

Current innovation and progress in hydrogen compressor technology

Faced with the rapid development of the hydrogen energy industry and the challenges of existing technologies, technological innovation and R&D investment in the field of hydrogen compressors have continued to increase, and significant progress has been made, mainly reflected in the following aspects:

High-pressure and large-scale trends:

Increased pressure level: With the popularization of the 70MPa hydrogen refueling standard for fuel cell vehicles and the future development of higher-pressure on-board hydrogen storage (such as 90MPa, 120MPa or even higher), hydrogen compressors are accelerating towards higher pressure levels. At present, commercial 70MPa hydrogen compressors are relatively mature, and some companies have developed 87.5MPa (for hydrogen station storage tanks) or even 90MPa, 100MPa compressor prototypes or products. Higher-pressure compressors can significantly increase hydrogen storage density, bringing greater flexibility to the storage and transportation of hydrogen energy.

Increased processing flow: In order to meet the needs of large hydrogen refueling stations and industrial hydrogen, the processing flow of a single hydrogen compressor is also increasing. For example, a large hydrogen refueling station may require a compressor that can process hundreds or even thousands of kilograms of hydrogen per hour. This requires compressor manufacturers to overcome a series of challenges such as heat dissipation, structural strength, and efficiency in design to achieve stable and efficient operation at large flows.

Efficient energy-saving technology:

Isothermal compression optimization: A large amount of heat is generated during the gas compression process, resulting in increased energy consumption. Researchers are working to improve the compression process by improving the cooling system (such as multi-stage cooling, medium cooling, liquid spray cooling, etc.) and the compression chamber design to make the compression process closer to the ideal isothermal compression, thereby improving compression efficiency and reducing energy consumption.

Variable frequency drive and intelligent control: The variable frequency motor drive technology can accurately adjust the compressor speed according to the actual load demand to avoid unnecessary energy loss. Combined with advanced intelligent control algorithms, the operating parameters of the compressor, such as suction pressure, exhaust pressure, temperature, etc., can be optimized in real time, so that it always operates at the optimal efficiency point, significantly reducing operating energy consumption.

Energy recovery system: Some advanced compressor systems have begun to integrate energy recovery modules to recycle the heat or other waste energy generated during the compression process, such as for preheating the intake air, driving auxiliary equipment or providing domestic hot water, further improving the overall energy efficiency of the system.

Long-life and high-reliability materials and structures:

Hydrogen embrittlement-resistant material research and development: Hydrogen embrittlement is a major challenge facing hydrogen compressors. Researchers are developing and applying new hydrogen-resistant materials, such as high-nickel alloys, austenitic stainless steel, special coatings, etc., to resist hydrogen penetration and induced material performance degradation, and extend the life of key compressor components (such as piston rods, cylinders, valves, diaphragms, etc.).

Optimized sealing technology: Hydrogen molecules are extremely small and easy to leak. High-reliability sealing is the key to ensuring compressor safety and efficiency. New sealing technologies, such as composite seals, magnetic fluid seals, labyrinth seals, etc., as well as more sophisticated processing techniques, are being used in hydrogen compressors to achieve ultra-low leakage rates and longer sealing life.

Modular design and integration: The modular design concept is adopted to integrate the compressor, cooling system, buffer tank, control unit, etc. into a compact skid-mounted unit, which not only simplifies installation and maintenance, but also improves the overall reliability of the system. The increased degree of integration also reduces pipes and connectors, thereby reducing the risk of leakage.

Intelligence and remote control:

Sensors and monitoring systems: Various sensors (pressure, temperature, flow, vibration, leakage detection, etc.) are widely deployed to monitor the operating status of the compressor in real time. Combined with the Internet of Things (IoT) technology, data can be uploaded to the cloud platform.

Fault diagnosis and predictive maintenance: Using big data analysis and artificial intelligence algorithms, the collected operating data is analyzed to achieve early warning and diagnosis of potential compressor failures, shifting from regular maintenance to predictive maintenance, greatly reducing unplanned downtime and improving equipment availability.

Remote control and optimization: Operation and maintenance personnel can monitor and control the compressor in real time through remote terminals, adjust parameters and handle faults, reduce on-site maintenance costs, and improve operation and maintenance efficiency.

Development of oil-free compression technology:

With the increasing requirements for hydrogen purity, oil-free compression technology has become mainstream. Diaphragm compressors continue to improve in diaphragm materials, structural design and fatigue life. Dry piston compressors continue to innovate in piston ring and seal materials to improve their wear resistance and self-lubrication.

Although ionic liquid compressors and liquid metal piston compressors are still in the research and development stage, their essential characteristics of oil-free and mechanical wear-free make them an important direction for high-purity, ultra-high-pressure hydrogen compression in the future.

Noise reduction and vibration reduction technology:

Especially for piston compressors, noise and vibration are their main disadvantages. Manufacturers have significantly reduced the operating noise and vibration of compressors by optimizing the design of the crank-connecting rod mechanism, using sound-absorbing materials, setting up vibration isolation foundations, and improving cooling air ducts, making them more suitable for places with high environmental requirements such as urban hydrogen refueling stations.

These technological innovations and progress have jointly promoted the development of hydrogen compressors towards a more efficient, reliable, intelligent and environmentally friendly direction, laying a solid technical foundation for the widespread application of hydrogen energy in the field of clean energy.

Conclusion

As a key hub in the hydrogen energy industry chain, the importance of hydrogen compressors is self-evident. It is not only a physical carrier for efficient storage and transportation of hydrogen, but also a key link in connecting hydrogen production, circulation and consumption. From hydrogen refueling stations to power fuel cell vehicles, to hydrogen supply for industrial production lines, to energy storage for hydrogen production from renewable energy in the future, hydrogen compressors play an irreplaceable role. Its significant advantages in increasing hydrogen storage density, reducing transportation costs, improving hydrogenation efficiency, ensuring fuel cell operation stability and promoting renewable energy consumption have jointly built the cornerstone of hydrogen energy economic development.

Despite this, the development of hydrogen compressor technology and industry has not been smooth sailing. We must face up to the many challenges it faces: high manufacturing costs and operating and maintenance costs are the primary bottlenecks restricting its large-scale promotion; the inherent flammable and explosive properties of hydrogen and the hydrogen embrittlement effect on materials have put extreme tests on the safety and reliability of equipment; the almost stringent requirements for hydrogen purity make oil-free compression technology an inevitable choice, but also increase the complexity of the technology; how to further improve energy efficiency and reduce compression energy consumption is the key to achieving hydrogen energy economy; and problems such as noise, vibration, lack of standardization and adaptability to extreme working conditions also need to be overcome one by one.

Looking ahead, the hydrogen compressor industry will continue to focus on technological innovation. High pressure and large-scale will be the needs for larger-scale hydrogen energy applications; high-efficiency energy-saving technologies, such as optimization, variable frequency drive and energy recovery that are closer to isothermal compression, will significantly reduce operating costs; the application of new materials and advanced sealing technologies will effectively extend equipment life and improve safety; intelligence, remote control and predictive maintenance will improve operational efficiency and reduce failure rates; and oil-free compression technology, especially the research and breakthrough of cutting-edge technologies such as ionic liquid and liquid metal piston compressors, will provide possibilities for ultra-high purity applications of hydrogen energy. At the same time, with the coordinated development of the global hydrogen energy industry, the establishment of unified international standards and specifications will help reduce R&D and production costs, promote market competition, and enhance the interconnectivity of global hydrogen energy infrastructure.

It can be foreseen that with the growing global demand for clean energy and the strong support of governments for the hydrogen energy industry, the hydrogen compressor market will usher in unprecedented development opportunities. Continuous investment in technology research and development, close cooperation between upstream and downstream of the industrial chain, and favorable policies and market environment will jointly promote hydrogen compressor technology to continuously break through bottlenecks and mature. Ultimately, efficient, safe, economical and reliable hydrogen compressors will become the key driving force for the popularization of hydrogen energy, contributing core strength to building a zero-carbon emission clean energy system and achieving global sustainable development goals.