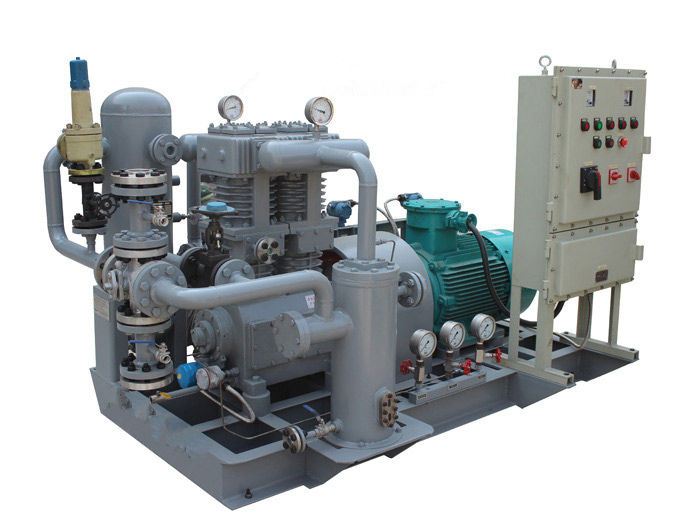

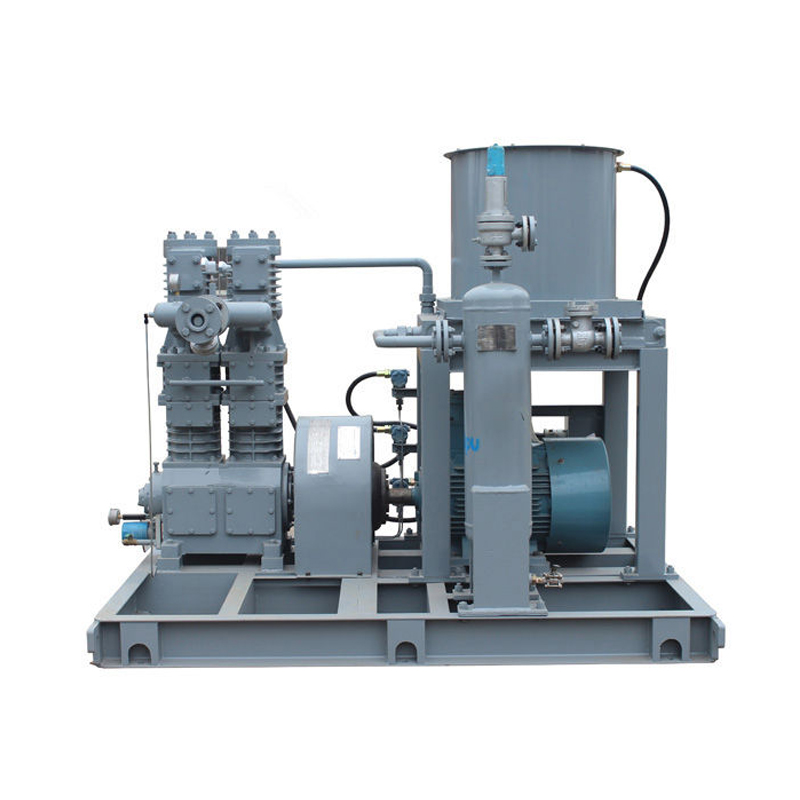

Ammonia compressor: the core power of industrial refrigeration and chemical processes

In the vast world of the industrial field, ammonia compressor, as a key equipment, are playing an indispensable role. Whether it is in the refrigeration industry to protect food preservation and cold chain logistics, or in the chemical industry to help various chemical reactions go smoothly, ammonia compressor have become the core power source of production and operation of many companies with their excellent performance and reliability. This article will deeply explore the characteristics, advantages and wide application of ammonia compressor in different industries, aiming to fully present the charm and value of this industrial weapon for you.

1.Working principle and technical highlights of ammonia compressor

ammonia compressor, like a tireless craftsman in the industrial field, cleverly use physical principles to compress ammonia, a special working fluid, to achieve energy conversion and transmission. Its basic working principle is based on the compressibility of gas. The motor drives the crankshaft connecting rod mechanism of the compressor to make the piston reciprocate in the cylinder. When the piston moves backward, the pressure in the cylinder decreases, and ammonia enters the cylinder from the suction valve; when the piston moves forward, the pressure in the cylinder increases, and the ammonia is compressed and discharged through the exhaust valve. In this way, the pressure of ammonia continues to rise, providing the necessary power for subsequent refrigeration or chemical processes.

In terms of technological innovation, modern ammonia compressor have shown remarkable highlights. First, the advanced compressor design adopts high-precision processing technology and optimized structural layout, which effectively reduces friction loss and improves mechanical efficiency. For example, the new cylinder inner wall coating technology not only enhances wear resistance, but also reduces the leakage of ammonia during the compression process, thereby improving the overall compression performance. Secondly, the application of intelligent control systems enables ammonia compressor to automatically adjust operating parameters according to actual working conditions and achieve accurate load matching. Through sensors to monitor the pressure, temperature, flow and other parameters of ammonia in real time, the control system can respond quickly to ensure that the compressor always operates in the best working state, which not only avoids energy waste, but also prolongs the service life of the equipment. In addition, some high-end ammonia compressor are also equipped with advanced oil separation technology, which can efficiently separate lubricating oil from ammonia, ensure the purity of the refrigeration system or chemical process flow, and prevent lubricating oil from causing adverse effects on equipment and products.

- The outstanding contribution of ammonia compressorin the refrigeration industry

In the field of refrigeration, ammonia compressor are well-deserved “refrigeration heart”. With the booming development of the global cold chain industry, the demand for efficient and reliable refrigeration equipment is growing. ammonia compressor, with their unique advantages, occupy an important position in many sub-sectors such as food processing, warehousing and logistics, and commercial refrigeration.

In the food processing industry, ammonia compressor provide a solid guarantee for the refrigeration, freezing and preservation of food. From large meat processing plants to fruit and vegetable preservation warehouses, ammonia refrigeration systems can accurately control temperature and humidity, effectively extend the shelf life of food, and maintain the freshness and taste of food. Compared with other refrigerants, ammonia has good thermodynamic properties, a large unit cooling capacity, and can achieve efficient refrigeration at lower pressures, thereby reducing the operating cost and energy consumption of the equipment. At the same time, ammonia is environmentally friendly, with zero ozone depletion potential (ODP) and extremely low global warming potential (GWP), which meets the strict requirements of today’s society for environmentally friendly refrigeration technology.

In the field of warehousing and logistics, the rapid rise of cold chain logistics has made the role of ammonia compressor more prominent. Modern cold storage and refrigerated transport vehicles widely use ammonia refrigeration systems to ensure that the quality of all kinds of perishable goods is not affected during storage and transportation. ammonia compressor can adapt to the refrigeration needs of cold storages of different sizes. Whether it is a small retail cold storage or a refrigerated warehouse in a large logistics distribution center, ammonia compressor can be used to build a stable and efficient refrigeration environment. Moreover, the reliability and durability of the ammonia refrigeration system enable it to maintain a low failure rate during long-term operation, reducing the loss of goods and increased operating costs caused by equipment failure.

In terms of commercial refrigeration, refrigerated display cabinets and ice machines in supermarkets, hotels, restaurants and other places also often use ammonia refrigeration technology. ammonia compressor can provide these commercial refrigeration equipment with a continuous and stable cold source to meet the operating requirements of frequent door opening and closing and different load changes. Its compact structural design and low-noise operation characteristics ensure that commercial refrigeration equipment will not cause too much interference to the surrounding environment and customers while ensuring the refrigeration effect, creating a comfortable and quiet shopping and consumption environment for consumers.

- The key role of ammonia compressorin the chemical industry

As one of the important pillar industries of the national economy, the chemical industry involves many complex chemical reactions and process flows. ammonia compressor play a vital role in it, providing indispensable pressure and power support for the smooth progress of chemical production.

In the synthetic ammonia production process, ammonia compressor are one of the core equipment of the entire production process. The synthetic ammonia reaction needs to be carried out under high temperature and high pressure conditions. The ammonia compressor is responsible for compressing the ammonia generated by the reaction, increasing its pressure and then transporting it to the subsequent separation, purification and storage links. By precisely controlling the compression ratio and flow rate of ammonia, it is ensured that the synthetic ammonia reaction can continue under stable process conditions, thereby achieving efficient ammonia synthesis production. At the same time, the reliability and stability of the ammonia compressor are directly related to the overall operating efficiency and safety of the synthetic ammonia unit. Once the compressor fails, it may cause the entire synthetic ammonia production line to stop production, causing huge economic losses to the company.

In the field of petrochemicals, ammonia compressor are widely used in natural gas liquefaction, petroleum refining and other process processes. In the natural gas liquefaction process, the ammonia compressor, as a key component of the refrigeration cycle, cools the natural gas to an extremely low temperature, liquefies it, and facilitates storage and transportation. Ammonia refrigeration system has the advantages of high refrigeration efficiency and large refrigeration capacity, and can meet the needs of large-scale natural gas liquefaction projects. In the process of oil refining, ammonia compressor are used to provide the pressure required for processes such as hydrogen compression. Hydrogen plays an important role in reactions such as oil hydrorefining and hydrocracking. The stable operation of ammonia compressor ensures that the supply pressure and flow of hydrogen meet the process requirements, thereby ensuring the quality and production efficiency of petroleum products.

In addition, ammonia compressor also have unique applications in the production of some fine chemicals and new chemical materials. For example, in some polymer synthesis reactions, it is necessary to accurately control the pressure and flow of ammonia to adjust the pH and reaction rate of the reaction system. ammonia compressor can provide a stable supply of ammonia for these fine chemical reactions, achieve precise control of the reaction process, and help produce high-quality and high-performance chemical products.

- Quality and reliability guarantee of ammonia compressor

For industrial enterprises, the quality and reliability of equipment are one of the key factors that determine the success or failure of production operations. In the design, manufacturing and after-sales service of ammonia compressor, we always put quality and reliability first and provide customers with comprehensive guarantees.

During the design phase, our professional R&D team fully considered the operating requirements of the ammonia compressor under different working conditions, and used advanced computer-aided design (CAD) and simulation analysis software to perform detailed calculations and optimization on the compressor’s structural strength, thermodynamic properties, and fluid dynamics characteristics. Through repeated simulation tests and verifications, we ensured the rationality and reliability of the design scheme, so that the ammonia compressor has good stability and durability while meeting high performance requirements.

During the manufacturing process, we strictly follow the international quality management system standards, and conduct strict quality control at every link from raw material procurement to parts processing, assembly and commissioning. We select high-quality steel, castings and parts to ensure that their materials meet the design requirements and have good mechanical properties and corrosion resistance. Advanced processing equipment and precision processing technology are used to ensure the processing accuracy and assembly quality of parts. After assembly, each ammonia compressor must undergo strict factory inspection, including performance testing, leakage detection, vibration detection and other inspection items. Only products that meet the standard requirements can be delivered to customers.

In terms of after-sales service, we have a professional after-sales technical team to provide customers with 24-hour technical support and services. Whether it is equipment installation and commissioning, daily maintenance or fault repair, we can respond to customer needs in a timely manner and quickly dispatch technicians to the site to solve problems. We also provide customers with regular return visits to understand the operation of the equipment, provide customers with advice and technical training on equipment maintenance, help customers improve equipment management level, extend equipment service life, and ensure that ammonia compressor can maintain good operating conditions throughout the service life cycle.

- Energy-saving and environmental protection advantages of ammonia compressor

In today’s era of advocating energy conservation, emission reduction and sustainable development, the advantages of ammonia compressor in energy conservation and environmental protection make them the first choice for many companies.

From the perspective of energy conservation, ammonia compressor achieve efficient use of energy through a series of advanced technical means. As mentioned above, the intelligent control system can automatically adjust the operating parameters of the compressor according to the actual working conditions, avoiding energy waste when the compressor is under low load or no-load conditions. In addition, the use of efficient motors and transmission systems, optimization of the internal flow channel design of the compressor, and reduction of resistance loss during compression have effectively improved the energy efficiency of ammonia compressor. Compared with traditional refrigeration and compression equipment, the new ammonia compressor can significantly reduce energy consumption, save a lot of operating costs for enterprises, and also meet the strict restrictions on energy consumption of industrial enterprises in countries and regions.

In terms of environmental protection, ammonia, as a natural refrigerant, has incomparable advantages. It does not damage the ozone layer and has little impact on global warming. As the international community increasingly restricts the use of traditional refrigerants such as Freon, ammonia refrigeration and compression technology is gradually becoming a mainstream trend. Refrigeration and chemical systems using ammonia compressor can greatly reduce the negative impact on the environment while meeting production needs, help enterprises achieve green production, and enhance the social image and competitiveness of enterprises.

- Wise decision to choose ammonia compressor

In summary, ammonia compressor, as core equipment in the field of industrial refrigeration and chemical processes, have become a key factor for many companies to achieve efficient production and sustainable development with their advanced working principles, outstanding technical highlights, wide application in different industries, reliable quality assurance, significant energy-saving and environmental protection advantages, and many successful application cases. Whether in traditional industries such as food, chemicals, oil and gas, or in emerging cold chain logistics, fine chemicals and other fields, ammonia compressor have demonstrated their unique value and charm.

If you are looking for a high-quality, high-performance equipment for refrigeration or compression needs in industrial production, then ammonia compressor are undoubtedly your wise choice. We will provide you with a one-stop solution with a professional technical team, high-quality products and a full range of after-sales services to help your company achieve greater success in the fierce market competition. Choosing an ammonia compressor means choosing high efficiency, reliability, energy saving and environmental protection. Let us work together to create a better future in the industrial field.

In the future development, with the continuous advancement of science and technology and the continuous growth of industrial demand, ammonia compressor will continue to innovate and improve, and contribute more to the development of global industry. We look forward to witnessing with you the more exciting performance of ammonia compressor on the industrial stage and jointly opening a new chapter in industrial production.