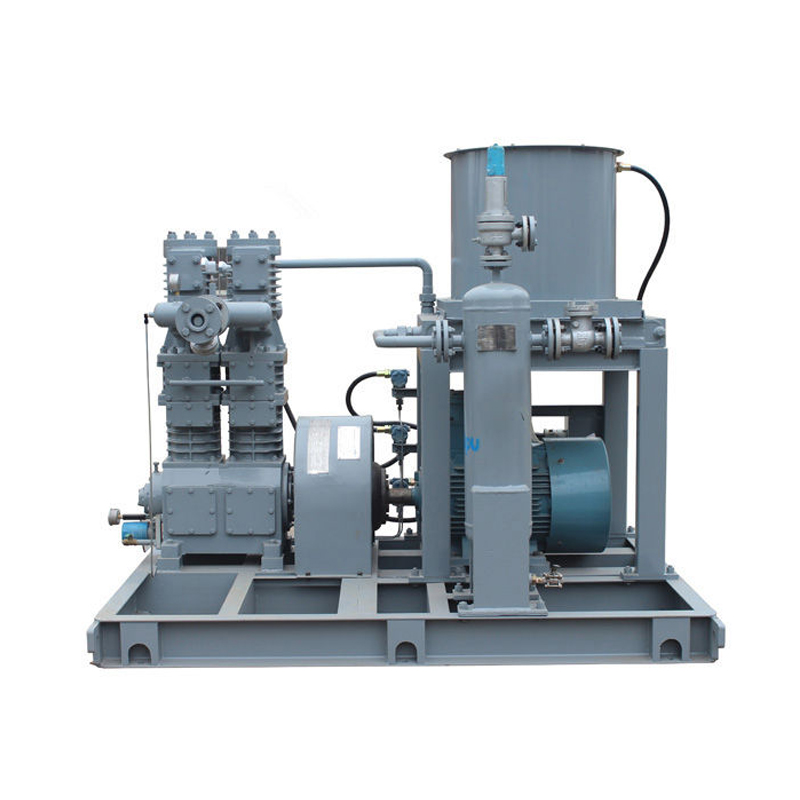

Ammonia Compressor

- Compressor type: ZW type piston compressor

- Motor power:5.5kw~55kw

- Voltage frequency :380V/50HZ (customizable)

- Cooling type: water cooling/air cooling (customizable)

- Cylinder type: vertical structure

Product Description

This series of oil-free lubricating compressors is one of the first products produced by our factory in China. The product has low rotational speed, high component strength, smooth operation, long service life, and easy maintenance. Among them, ZW series compressors are in unit form. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, check valve, explosion-proof motor and chassis. It has the characteristics of small size, light weight, low noise, good sealing, easy installation and simple operation.

This product is mainly used for unloading, loading, tank dumping, residual gas recovery and residual liquid recovery of liquefied petroleum gas/C4, propylene and liquid ammonia. It is widely used in gas, chemical, energy and other industries and is a key equipment in gas, chemical, energy and other industries.

Note: During the unloading process, the compressor pressurizes the gas from the storage tank and then presses it into the tanker through the gas phase pipeline. The pressure difference in the gas phase presses the liquid from the tanker to the storage tank to complete the unloading process. When the gas phase is pressurized, the gas phase temperature will increase. At this time, there is no need for forced cooling, because if the gas phase is compressed and then cooled, it will easily liquefy, making it difficult to establish a gas phase pressure difference, which is not conducive to the replacement of the gas phase and the liquid phase. In short, it will prolong the unloading process. If residual gas recovery is required, a cooler can be selected to force-cool the gas phase during the residual gas recovery operation so that the residual gas can be recovered as quickly as possible.

The loading process is the opposite of the unloading process.

Technical Parameters and Specifications

| __NO | Model | (Nm3/h) | Inlet pressure (Mpa) | Outlet pressure (Mpa) | Moter Power (KW) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| 1 | ZW-0.6/16-24 | 550 | 1.6 | 2.4 | 11 | 1000×580×870 |

| 2 | ZW-0.8/16-24 | 750 | 1.6 | 2.4 | 15 | 1000×580×870 |

| 3 | ZW-1.0/16-24 | 920 | 1.6 | 2.4 | 18.5 | 1000×580×870 |

| 4 | ZW-1.5/16-24 | 1380 | 1.6 | 2.4 | 30 | 1000×580×870 |

| 5 | ZW-2.0/16-24 | 1500 | 1.6 | 2.4 | 37 | 1000×580×870 |

| 6 | ZW-2.5/16-24 | 1880 | 1.6 | 2.4 | 45 | 1000×580×870 |

| 7 | ZW-3.0/16-24 | 2250 | 1.6 | 2.4 | 55 | 1000×580×870 |

| 8 | ZW-0.8/10-16 | 450 | 1.0 | 1.6 | 11 | 1100×740×960 |

| 9 | ZW-1.1/10-16 | 600 | 1.0 | 1.6 | 15 | 1100×740×960 |

| 10 | ZW-1.35/10-16 | 750 | 1.0 | 1.6 | 18.5 | 1100×740×960 |

| 11 | ZW-1.6/10-16 | 950 | 1.0 | 1.6 | 22 | 1400×900×1180 |

| 12 | ZW-2.0/10-16 | 1200 | 1.0 | 1.6 | 30 | 1400×900×1180 |

| 13 | ZW-2.5/10-16 | 1500 | 1.0 | 1.6 | 37 | 1400×900×1180 |

| 14 | ZW-3.0/10-16 | 1800 | 1.0 | 1.6 | 45 | 1400×900×1180 |

| 15 | ZW-0.6/16-24 | 550 | 1.6 | 2.4 | 11 | 1500x800x1100 |

| 16 | ZW-0.8/16-24 | 750 | 1.6 | 2.4 | 15 | 1500×800×1100 |

| 17 | ZW-1.0/16-24 | 920 | 1.6 | 2.4 | 18.5 | 1500×800×1100 |

| 18 | ZW-1.5/16-24 | 1380 | 1.6 | 2.4 | 30 | 1600×900×1200 |

| 19 | ZW-2.0/16-24 | 1500 | 1.6 | 2.4 | 37 | 1600x900x1200 |

| 20 | ZW-2.5/16-24 | 1880 | 1.6 | 2.4 | 45 | 1600×900×1200 |

| 21 | ZW-3.0/16-24 | 2580 | 1.6 | 2.4 | 55 | 1600×900×1200 |

| 22 | ZW-3.5/16-24 | 3000 | 1.6 | 2.4 | 55 | 1600×900×1200 |

| 23 | ZW-4.0/16-24 | 3500 | 1.6 | 2.4 | 75 | 1600x900x1200 |

| 24 | ZW-0.2/10-25 | 100 | 1 | 2.5 | 5.5 | 1000×580×870 |

| 25 | ZW-0.4/10-25 | 220 | 1 | 2.5 | 11 | 1000×580×870 |

| 26 | ZW-0.6/10-25 | 330 | 1 | 2.5 | 15 | 1000×580×870 |

| 27 | ZW-0.2/25-40 | 260 | 2.5 | 4 | 7.5 | 1000×580×870 |

| 28 | ZW-0.4/25-40 | 510 | 2.5 | 4 | 15 | 1000×580×870 |

| 29 | ZW-0.5/25-40 | 660 | 2.5 | 4 | 18.5 | 1000×580×870 |

| 30 | ZW-0.3/20-30 | 300 | 2 | 3 | 7.5 | 1000×580×870 |

| 31 | ZW-0.4/20-30 | 420 | 2 | 3 | 11 | 1000x580x870 |

| 32 | ZW-0.5/20-30 | 540 | 2 | 3 | 15 | 1000×580×870 |

| 33 | ZW-0.6/20-30 | 630 | 2 | 3 | 15 | 1000×580×870 |

| 34 | ZW-1.6/20-30 | 1710 | 2 | 3 | 37 | 1400×900×1180 |