Special gas compressors are equipment specially designed for compressing and delivering a variety of gases, and are widely used in industries such as chemical, medical and electronics. They are capable of handling high-purity gases such as nitrogen, oxygen, helium, hydrogen, carbon dioxide and fluorinated gases, ensuring safe and stable operation under high pressure and high temperature environments.

These compressors are usually equipped with multi-stage compression systems and advanced control devices to optimize efficiency and safety. Due to the different properties of special gases, they use corrosion-resistant materials and sealing technology to prevent leakage and ensure the purity and safety of the gas. Whether in laboratories or industrial production, special gas compressors are key equipment.

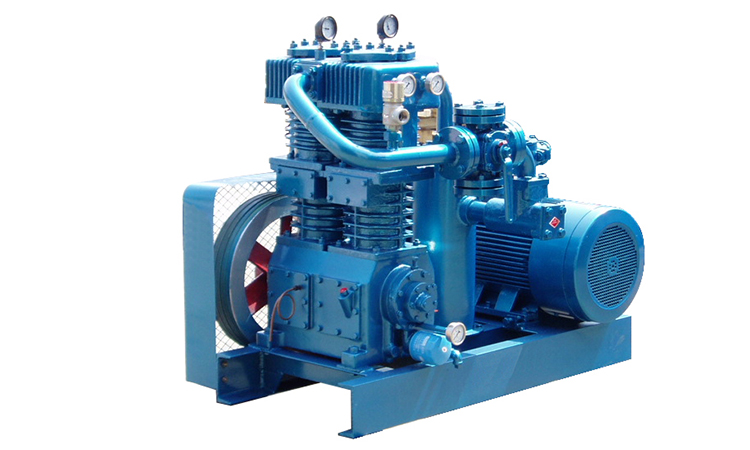

Hydrogen Compressor

Hydrogen compressors are specially designed for efficient compression and delivery of hydrogen, and are widely used in energy, chemical, automotive and other industries. With the rapid development of hydrogen energy technology, hydrogen compressors play a key role in fuel cells, water electrolysis, hydrogen production and hydrogen storage.

Flow rate: 10~1800 Nm³/h

Pressure: ≤35MPa

Medium: Hydrogen

Control: PLC automatic control

Drive mode: Motor

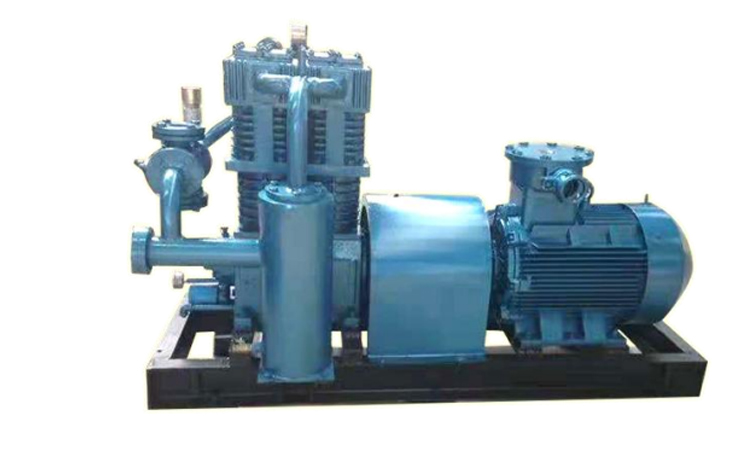

Nitrogen Booster Compressor

Nitrogen booster compressor is a kind of equipment specially designed to increase the pressure of nitrogen, which is widely used in chemical industry, food packaging and welding industry. This compressor ensures the safe and stable supply of nitrogen under high pressure through multi-stage compression technology to meet the needs of industrial production and gas protection.

Flow rate: <4800 Nm³/hr

Pressure: <40 MPa

Medium: nitrogen, helium, argon

Control: PLC automatic control

Drive mode: motor, diesel engine

Membrane Nitrogen Compressor

The skid-mounted membrane nitrogen production high-pressure nitrogen injection system (900m³/h-95%N2) is based on our factory’s professional technology. This complete system can work normally in relatively harsh working environments (-30℃~+45℃, windy and sandy environments, rainy and snowy weather), and is used to produce high-pressure nitrogen below 35MPa with a nitrogen purity of 90%-99% at the work site.

Flow rate: 100~1800 Nm³/h

Pressure: 2~ 40 MPa

Control: PLC automatic control

Drive mode: motor, diesel engine

Cooling mode: air cooling, water cooling, mixed cooling

Ammonia, Refrigeration Compressor

Ammonia refrigeration compressor is a device specially used to compress ammonia, which is widely used in refrigeration and air conditioning systems. Ammonia is an ideal choice for industrial refrigeration due to its high thermal conductivity and low environmental impact. The compressor uses multi-stage compression technology to achieve high efficiency and stable refrigeration effect, and is suitable for food processing, refrigeration and cold chain logistics.

Our company has developed various types of compressors specifically for refrigerant recovery and repackaging, suitable for media such as R22; R134A; R404A; R410A; R507; R407C; R406A; R415B; R409A, Freon, etc.

Carbon Dioxide Compressor

The skid-mounted membrane nitrogen production high-pressure nitrogen injection system (900m³/h-95%N2) is based on our factory’s professional technology. This complete system can work normally in relatively harsh working environments (-30℃~+45℃, windy and sandy environments, rainy and snowy weather), and is used to produce high-pressure nitrogen below 35MPa with a nitrogen purity of 90%-99% at the work site.

Flow rate: 10~1800 Nm³/hr

Exhaust pressure: ≤15 MPa

Medium: CO2

Control: PLC automatic control

Propylene Compressor

Ammonia refrigeration compressor is a device specially used to compress ammonia, which is widely used in refrigeration and air conditioning systems. Ammonia is an ideal choice for industrial refrigeration due to its high thermal conductivity and low environmental impact. The compressor uses multi-stage compression technology to achieve high efficiency and stable refrigeration effect, and is suitable for food processing, refrigeration and cold chain logistics.

SOLLANT has designed and manufactured propylene unloading, propylene vacuuming and propylene booster compressors specifically for the above industries and processes. The machine is characterized by compact structure, high efficiency, stable operation and high reliability.

Butadiene Compressor

The ZW type butadiene compressor is a vertical, oil-free reciprocating piston circulating compressor. The compressor cylinder and packing parts are oil-free lubricated to ensure the purity of its working medium. The crankshaft, connecting rod and crosshead parts are splash-slip to ensure the reliability of lubrication. It integrates the compressor, motor, air pipeline system and four-way valve into one, making installation and operation more convenient

The stuffing box of the machine is made of multiple pieces of special polytetrafluoroethylene materials, which can fully ensure the sealing of the gas. At the same time, the crankshaft connecting rod is lubricated by oil pump, which ensures that the compressor can obtain sufficient lubrication and is easy to detect.

Oxygen Compressor

Oxygen compressor is a kind of equipment specially used for compressing oxygen, which is widely used in medical, welding, chemical and water treatment industries.

Compressed medium: oxygen

Exhaust volume: 50Nm3/h-300Nm3/h

Intake pressure: 0-0.4MPa

Exhaust pressure: 15.0MPa

Compression stage: 4

Compressor speed: 740r/min

Compressor stroke: 80mm

Cooling method: air cooling

Motor power: 11KW-75KW

Other Special Media Compressors

| Model | Medium | Inlet displacement m³/min | Inlet pressure MPa | Exhaust pressure MPa | Motor power kW |

|---|---|---|---|---|---|

| VW-3.2/0.03-19 | Propane | 3.2 | 0.003 | 1.9 | 30 |

| VW-3.5/0.5-20 | Propane | 3.5 | 0.05 | 2.0 | 55 |

| VW-12/0.04-22 | Propane | 12 | 0.004 | 2.2 | 132 |

| DW-1.2/30-170 | Carbon monoxide | 1.2 | 3.0 | 17 | 185 |

| VW-6/3 | Carbon monoxide | 6 | Slightly positive pressure | 0.3 | 37 |

| ZW-1.1/(7-12)-85 | Carbon monoxide | 1.1 | 0.7-1.2 | 8.5 | 75 |

| DW-2.5/(3-5)-85 | Carbon monoxide | 2.5 | 0.3-0.5 | 8.5 | 110 |

| DW-9/3 | Analysis gas | 9 | Slightly positive pressure | 0.3 | 37 |

| VW-15/3 | Gas | 15 | Slightly positive pressure | 0.3 | 75 |

| VW-12/4 | Gas | 12 | Slightly positive pressure | 0.4 | 55 |

| VW-4/(0-6)-6 | Isobutylene | 4 | 0-0.06 | 0.6 | 37 |

| DW-8/0.3-8 | Isobutylene | 8 | 0.03 | 0.8 | 75 |

| ZW-1.8/3-39 | Flash gas | 1.8 | 0.3 | 3.9 | 55 |

| WW-6.3/0.2-12 | Non-condensable gas | 6.3 | 0.02 | 1.2 | 55 |

| DW-5.5/5.5-20 | Raw gas | 5.5 | 0.55 | 2.0 | 132 |

| DW-7.8/2-24 | Associated gas | 7.8 | 0.2 | 2.4 | 160 |

| ZW-5/0.2-2.5 | Tail gas | 5 | 0.02 | 0.25 | 22 |

| VW-15/2 | Tail gas | 15 | Slightly positive pressure | 0.2 | 55 |

| ZW-0.8/8-12 | Vinyl chloride | 0.8 | 0.8 | 1.2 | 11 |

| ZW-4.2/8-13 | Rich gas | 4.2 | 0.8 | 1.3 | 55 |

| DW-20/0.5-15 | Rich gas | 20 | 0.5 | 1.5 | 200 |

| VW-6/4 | Butane | 6 | Slightly positive pressure | 0.4 | 37 |

| ZW-4/2 | Ethylene | 4 | Slightly positive pressure | 0.2 | 22 |

| ZW-0.8/16-24 | Ethylene/ethyl chloride | 0.8 | 1.6 | 2.4 | 18.5 |

| ZW-1.5/8-15 | Butadiene | 1.5 | 0.8 | 1.5 | 22 |

| DW-30/0.2-4.2 | Butadiene-end | 30 | 0.02 | 0.42 | 160 |

| ZW-0.5/0.1-16 | Tail gas | 0.5 | 0.01 | 1.6 | 5.5 |

| ZW-1/3 | Smelly methane | 1 | Slightly positive pressure | 0.3 | 5.5 |

| ZW-0.6/10 | Straw gas | 0.6 | Slightly positive pressure | 1.0 | 7.5 |

| ZW-0.8/8 | Biogas | 0.8 | Slightly positive pressure | 0.8 | 7.5 |

| VW-15/3 | Biogas | 15 | Slightly positive pressure | 0.3 | 55 |

| ZW-0.7/(0-5)-5 | Methyl chloride | 0.7 | 0-0.05 | 0.5 | 5.5 |

| ZW-3/10 | Methyl chloride | 3 | Slightly positive pressure | 1.0 | 30 |

| VW-13/(0-4)-5 | Methyl chloride | 13 | 0-0.04 | 0.5 | 90 |

| VW-9.3/(1-10)-10 | Methyl chloride | 9.3 | 0.1-1 | 1.0 | 132 |

| WW-5.2/25 | Freon | 5.2 | Slightly positive pressure | 2.5 | 45 |

| ZW-4/2-8 | dimethyl ether | 4 | 0.2 | 0.8 | 37 |

| DW-13.5/1-8.5 | dimethyl ether | 13.5 | 0.1 | 0.85 | 132 |

| DW-10/1-8.5 | dimethyl ether | 10 | 0.1 | 0.85 | 90 |

| WW-5/0.2-7 | oxygen | 5 | 0.02 | 0.7 | 45 |

| ZW-0.3/3-150 | oxygen | 0.3 | 0.3 | 15 | 22 |

| ZW-1.2/2-150 | oxygen | 1.2 | 0.2 | 15 | 45 |

| VW-6/(0-0.1)-8 | hydrogen | 6 | 0-0.01 | 0.8 | 55 |

| ZW-0.8/4-8 | Low temperature ethylene | 0.8 | 0.4 | 0.8 | 7.5 |

| VW-6/21 | Low temperature ethylene | 6 | Slightly positive pressure | 2.1 | 75 |

| WW-10/16 | Difluoroethane | 10 | Slightly positive pressure | 1.6 | 110 |

| ZW-1/20 | Pentafluoroethane | 1 | Slightly positive pressure | 2.0 | 18.5 |

| WW-3/(0.05-1)-35 | Vinylidene fluoride | 3 | 0.005-0.1 | 3.5 | 55 |

| VW-4.8/0.5-45 | Vinylidene fluoride | 4.8 | 0.05 | 4.5 | 110 |

| DW-3/0.03-10 | Chlorodifluoroethane | 3 | 0.003 | 1.0 | 37 |

| DW-40/0.5-4.5 | Gas | 40 | 0.05 | 0.45 | 220 |

| VW-33/6 | Gas | 33 | Slightly positive pressure | 0.6 | 200 |

| VW-50/7 | Gas | 50 | Slightly positive pressure | 0.7 | 315 |

| WW-40/6.5 | Vinyl chloride | 40 | Slightly positive pressure | 0.65 | 250 |

| DW-15.5/5.5 | Large tank exhaust | 15.5 | Slightly positive pressure | 0.55 | 90 |

| VW-25/7 | Coke oven gas | 25 | Slightly positive pressure | 0.7 | 160 |

| VW-32/6 | Fuel gas | 32 | Slightly positive pressure | 0.6 | 185 |

| DW-30/0.02-2 | Coal bed methane | 30 | 0.002 | 0.2 | 110 |