Steel production is the cornerstone of modern industry and has a profound impact on the development of the economy and infrastructure. As a core link in heavy industry, steel production involves a large amount of energy consumption and raw material use. The steel production process usually includes the smelting of ore to the processing of finished steel, which requires a high temperature and efficient reaction environment to ensure the quality and production efficiency of the final product.

In the steel production process, blast furnace ironmaking and converter steelmaking are the two main production links. These processes require a lot of heat energy and oxygen to maintain high temperature reactions and optimize chemical reactions to produce high-quality steel products. Therefore, oxygen, as a key auxiliary material, plays an important role in improving production efficiency, improving product quality and reducing energy consumption.

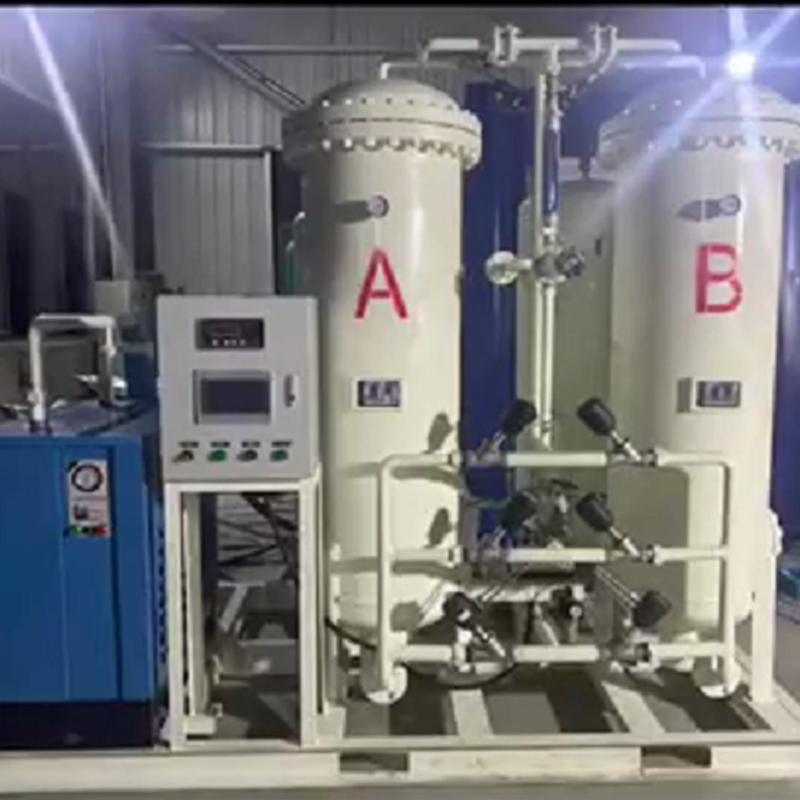

Industrial oxygen generator is a device specially used to separate and extract oxygen from air. Its basic function is to separate oxygen from other gases (such as nitrogen, carbon dioxide) in the air and provide high-purity oxygen for industrial applications. The working principles of industrial oxygen generators are mainly as follows:

- Pressure swing adsorption (PSA) technology: By compressing air and passing it through a specific adsorption material, oxygen and nitrogen are separated by utilizing the adsorption characteristics of different gases on the material. PSA oxygen generators have the advantages of simple operation and low maintenance cost.

- Vacuum pressure swing adsorption (VPSA) technology: Similar to PSA, but a vacuum system is used during operation to improve the separation efficiency of oxygen. Suitable for application scenarios that require a large flow of oxygen.

- Liquid oxygen preparation technology: By cooling air to a liquefied state and then distilling out oxygen. Liquid oxygen preparation equipment is usually used in large industrial applications that require high-purity oxygen.

These oxygen production technologies can provide a stable and reliable supply of oxygen according to different industrial needs, and help steel production companies improve production efficiency, reduce energy costs and improve product quality by optimizing the purity and flow of oxygen. By adopting industrial oxygen generators, steel production companies can achieve more efficient production processes and promote sustainable development of the industry.