Oilfield Oil Well Gas Compressors: An In-Depth Analysis of Efficiently Recovering and Utilizing Associated Gas to Achieve Cost Reduction and Increased Efficiency

Against the backdrop of global energy transition and increasing pressure on environmental protection, oil and gas field development faces unprecedented challenges and opportunities. The processing and utilization of associated gas from oilfields, a crucial step in the oil and gas production process, is directly related to a company’s economic benefits, environmental performance, and even its social image. Traditional associated gas processing methods, such as direct venting or flaring, not only result in significant energy waste and greenhouse gas emissions, but are also inconsistent with the concept of sustainable development. This article will delve into the critical role of oilfield oil well gas compressors in associated gas recovery and utilization. From multiple perspectives, including the sources and characteristics of associated gas, the operating principles of compressors, efficient recovery technology paths, economic benefits and environmental implications, and cost reduction and efficiency improvement strategies, this article will comprehensively analyze how efficient recovery and utilization of associated gas can achieve green and sustainable development for oil and gas field companies.

Sources and Characteristics of Associated Gas from Oilfields

Associated Petroleum Gas (APG), also known as associated gas or solution gas, refers to the natural gas produced simultaneously with crude oil during oil production. Its formation is closely related to the generation, migration, and accumulation of crude oil. It is typically dissolved in crude oil or present in a free state in oil reservoirs.

Source and Compositional Complexity:

Associated gas is primarily composed of methane, but it also contains a certain proportion of heavier hydrocarbons such as ethane, propane, and butane, as well as smaller amounts of non-hydrocarbon components such as carbon dioxide, hydrogen sulfide, nitrogen, and water vapor. The specific compositional ratios vary significantly depending on the oilfield geology, crude oil properties, development stage, and recovery method. For example, associated gas from light oil fields may contain a higher methane content, while associated gas from heavy oil fields may contain more heavy hydrocarbons and non-hydrocarbon components. Associated gas from high-sulfur oil fields has a high hydrogen sulfide content and requires desulfurization treatment.

Pressure and Flow Volatility:

The production pressure and flow of associated gas are affected by a variety of factors, including well production performance, production technology, and reservoir energy fluctuations, resulting in significant fluctuations and instability. Associated gas production may be high during the initial production phase of a well and gradually decrease as reservoir pressure decreases. At the same time, due to variations in individual well production, the pressure and flow rate of associated gas produced from different wells can vary significantly, posing challenges to associated gas gathering, transportation, and processing. For example, measures such as intermittent oil production or stratified water injection can result in transient fluctuations in associated gas flow rates.

High Impurity Content:

During the production process, associated gas is often accompanied by impurities such as crude oil, formation water, silt, and corrosion products. If these impurities enter the compressor or subsequent processing equipment without treatment, they can severely impact equipment efficiency and lifespan, and even cause equipment failure. For example, the presence of liquid hydrocarbons and water vapor can cause compressor fluid shock, while solid particles can accelerate equipment wear. The presence of hydrogen sulfide can also cause equipment corrosion.

Calor Value and Utilization Potential:

Despite the aforementioned complexity and instability of associated gas, it remains a valuable energy source. Its primary component, methane, is a high-quality fuel with a high calorific value. If effectively recovered and utilized, it can be used as fuel gas for oilfield production (such as gas turbine power generation and heating furnace fuel), or, after treatment, as a chemical feedstock or city gas supplement, offering significant economic and environmental benefits. For example, in remote oil fields, associated gas can be used to generate electricity locally, addressing production power requirements and reducing reliance on external power grids.

Working Principle of Oilfield Oil Well Gas Compressors

Oilfield oil well gas compressors are a core component of associated gas recovery and utilization systems. Their primary function is to boost low-pressure associated gas to a higher pressure to meet subsequent gathering, transportation, processing, or utilization needs.

Basic Principle:

A gas compressor converts mechanical energy into gas pressure energy. The reciprocating motion or high-speed rotation of a piston or rotor reduces the volume of low-pressure gas, thereby increasing its pressure. Common gas compressors are categorized into two main types based on their compression method: positive displacement compressors and velocity compressors.

Positive Displacement Compressors:

Reciprocating Compressors (Piston Compressors): This is the most common type of compressor used in oilfields. They utilize the reciprocating motion of a piston within a cylinder to change the cylinder volume, thereby achieving gas intake, compression, and discharge. Reciprocating compressors offer a wide pressure and flow range, operate stably and reliably, and are particularly suitable for boosting medium- and low-pressure, high-flow associated gas. Its advantages are high efficiency and adaptability, but its disadvantages include high vibration, high noise, and the need for regular maintenance. Multi-stage compression can achieve higher compression ratios.

Single-stage vs. multi-stage compression: Depending on the required outlet pressure and compression ratio, reciprocating compressors can be designed as single-stage or multi-stage. Multi-stage compression effectively reduces compression power consumption, improves efficiency, and controls exhaust temperature by compressing the gas in stages and providing cooling between stages.

Lubrication system: Reciprocating compressors require lubricating oil to lubricate and cool moving parts. Selecting the right lubricant and regularly maintaining the lubrication system are crucial to ensure proper compressor operation and extend its life.

Sealing technology: Rod seals, valve seals, and other components are crucial for preventing gas leakage and maintaining compression efficiency.

Screw compressors: A pair of intermeshing helical rotors rotate, drawing, compressing, and discharging gas in the volume between the teeth. Screw compressors offer compact structure, smooth operation, low vibration, and low noise. They are also tolerant to small amounts of liquid droplets in the gas and are suitable for applications where associated gas contains small amounts of liquid. Its disadvantage is that it may not be as efficient as reciprocating compressors under high-flow, high-pressure differential conditions.

Dry vs. Oil-Injected: Screw compressors are categorized as dry or oil-injected. Oil-injected screw compressors use lubricating oil injected into the compression chamber to provide sealing, cooling, and lubrication, resulting in higher efficiency and lower noise.

Speed Compressor (Dynamic Compressor):

Centrifugal compressors utilize a high-speed rotating impeller to apply work to the gas, imparting kinetic energy to the gas. This energy is then converted to pressure energy through a diffuser. Centrifugal compressors offer advantages such as high flow rates, smooth operation, no reciprocating parts, and minimal maintenance, making them suitable for high-flow, low-pressure differential applications. However, they are less adaptable to fluctuations in gas flow and pressure, and their startup and shutdown procedures are more complex.

Multi-Stage vs. Single-Stage: Centrifugal compressors can also be designed with multiple stages to achieve higher discharge pressures.

Surge and Anti-Surge Control: Centrifugal compressors are subject to surge, which is unstable operation at low flows. Therefore, advanced anti-surge control systems are required to ensure safe operation. Axial-flow compressors: Gas flows axially through multiple impellers and guide vanes, increasing pressure step by step. Axial-flow compressors offer higher flow rates and efficiency, but their complex structure makes them commonly used in large gas turbines and aircraft engines, and less commonly in oilfield associated gas recovery.

Auxiliary Systems:

In addition to the compressor itself, oilfield oil well gas compressor systems also include a range of auxiliary equipment, such as:

Inlet gas separators: Used to separate liquid and solid impurities from associated gas to protect the compressor.

Chillers: Cool the gas between compression stages or at the compressor outlet, reducing gas temperature, improving compression efficiency, and meeting subsequent process requirements.

Buffer tanks: Balance inlet pressure and flow fluctuations to ensure stable compressor operation.

Control systems: Monitor and control compressor operating parameters such as pressure, temperature, flow, and vibration, enabling automation and remote control.

Drive: The power source that drives the compressor, which can be a gas engine, electric motor, or gas turbine.

Technical Pathways for Efficient Recovery and Utilization of Associated Gas

Efficient recovery and utilization of associated gas involves a series of advanced technologies and processes designed to maximize the added value of associated gas and minimize environmental impact.

Associated Gas Pretreatment Technologies:

Before associated gas enters the compressor and subsequent processing equipment, it must undergo rigorous pretreatment to remove impurities and ensure stable operation of subsequent equipment.

Gas-Liquid Separation: Utilizes equipment such as cyclones, gravity separators, and coalescing separators to effectively separate crude oil and formation water from associated gas. The effectiveness of this separation directly impacts the efficiency and lifespan of the compressor and subsequent dehydration and desulfurization equipment.

Solid-Liquid Separation: Utilizes filters, cyclones, and other devices to remove solid particles from the gas, preventing equipment wear and clogging.

Dehydration: Associated gas typically contains water vapor, which easily forms hydrates under low temperature and high pressure, potentially clogging pipelines and equipment. Common dehydration methods include:

T-Amine Dehydration (TEG Dehydration): Utilizes liquid desiccants such as ethylene glycol or triethylene glycol to absorb water vapor. This method is highly efficient and suitable for large-scale dehydration. Molecular sieve dehydration: Utilizes the adsorption properties of molecular sieves to remove water vapor, achieving a very low dew point. This method is suitable for applications requiring high gas purity.

Refrigeration dehydration: By lowering the gas temperature to condense and separate water vapor, it is suitable for dehydrating hydrocarbon-rich gas and recovering liquid hydrocarbons.

Desulfurization: Desulfurization is essential for associated gas containing hydrogen sulfide to meet environmental emission standards and subsequent utilization requirements.

Amine desulfurization: Utilizes an amine solution to absorb hydrogen sulfide, which is then regenerated by heating. This is a mature and widely used desulfurization technology.

Dry desulfurization: Utilizes solid adsorbents (such as iron oxide and activated carbon) to adsorb hydrogen sulfide. This method is suitable for small-scale or low-concentration hydrogen sulfide removal.

Catalytic oxidation desulfurization: Catalytically oxidizes hydrogen sulfide to elemental sulfur, while simultaneously recovering the sulfur.

Associated gas gathering, transportation, and pressurization technologies:

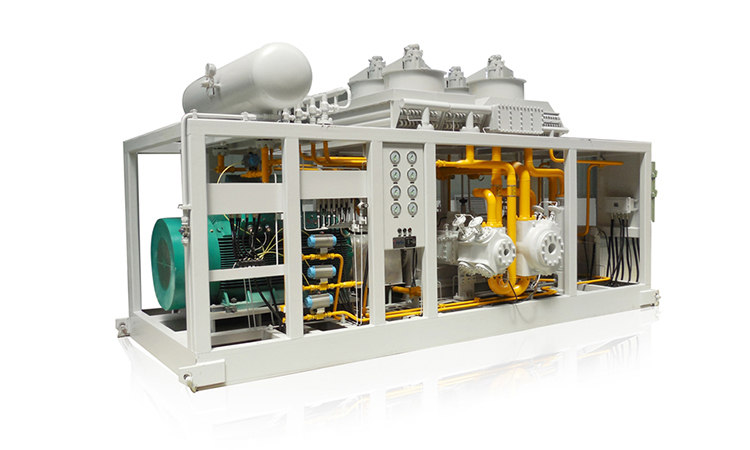

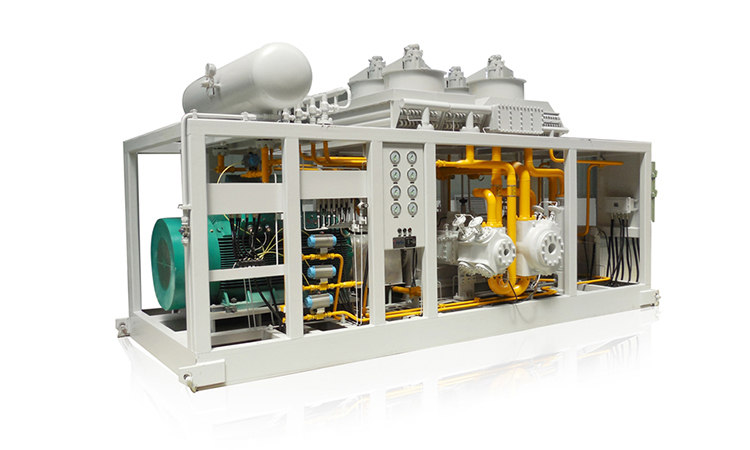

Rational pipeline network design: Based on the dispersed production points and fluctuating flow rates of associated gas in oil fields, the gathering and transportation pipeline network design is optimized to minimize pressure drop and reduce transportation energy consumption. Skid-Mounted Compressor Stations: For dispersed associated gas sources, skid-mounted (modular) compressor stations are used for rapid deployment and relocation, reducing project costs and construction time. The skid-mounted design integrates all necessary equipment, including compressors, separators, coolers, and control systems.

Stage-Based Boosting: Based on the associated gas production pressure and utilization requirements, multi-stage compression or multiple stations in series are used for staged boosting to ensure efficient compressor operation and meet target pressures.

Associated Gas Utilization:

Converting recovered associated gas into valuable products or energy is the key to its efficient utilization.

Fuel Gas Utilization:

In-Oilfield Fuel: The most direct and common utilization method is to use associated gas as fuel for oilfield heaters, boilers, generator sets, gas turbines, and other equipment, replacing purchased fuel and reducing operating costs. This can effectively address electricity and heat requirements for oilfield production, especially in remote areas.

Power Generation: Associated gas is used to power gas-fired generators, generating electricity for internal use within the oilfield or for grid-connected sales, generating additional revenue. Gas turbines are an ideal choice for power generation due to their high efficiency and low emissions. Compressed Natural Gas (CNG)/Liquefied Natural Gas (LNG): After purification, dehydration, and removal of heavy hydrocarbons, associated gas is liquefied or compressed and can be used as vehicle fuel or city gas supplement. This requires the construction of specialized liquefaction or compression equipment, which carries significant investment, but the market prospects are broad.

Chemical Raw Materials:

Methanol Production: Methane in associated gas is a key raw material for methanol production. Methanol is an important basic chemical product used in the production of olefins, acetic acid, formaldehyde, and other products.

Synthetic Ammonia/Urea Production: Associated gas can also serve as a feedstock for synthetic ammonia, which is then used to produce nitrogen fertilizers such as urea.

Ethane, Propane, and Butane (NGL) Purification: Heavy hydrocarbons such as ethane, propane, and butane separated from associated gas are important chemical raw materials for the production of high-value-added products such as plastics and rubber. This typically requires cryogenic separation technology.

Reinjection into Reservoirs:

In some cases, associated gas can be reinjected into reservoirs to maintain reservoir pressure, enhance oil recovery, and simultaneously store gas. This is a method of utilization that combines enhanced oil recovery with environmental protection. However, the quality and pressure requirements for reinjected gas are high.

Intelligent and Automated Control:

Remote Monitoring and Diagnosis: Advanced SCADA systems and IoT technologies are introduced to enable real-time remote monitoring of the associated gas recovery and utilization system, including parameters such as pressure, temperature, flow rate, and equipment operating status. This allows for timely detection and resolution of anomalies, improving operational reliability.

Optimized Operational Control: Based on real-time data and predictive models, operational strategies such as compressor start-up and shutdown, load regulation, and process switching are optimized to maximize energy efficiency and reduce energy consumption.

Fault Warning and Diagnosis: Utilizing big data analysis and artificial intelligence technologies, in-depth mining of equipment operating data enables early warning and accurate diagnosis of faults, reducing downtime and increasing equipment utilization.

Economic Benefits and Environmental Implications of Associated Gas Recovery

Efficient recovery and utilization of associated gas not only brings significant economic returns but also has far-reaching environmental benefits.

Economic Benefits:

Energy Savings and Substitution: Converting associated gas into usable energy directly replaces externally purchased energy sources such as diesel and electricity used in oilfield production, significantly reducing operating costs. For oilfield self-generated electricity, the cost of associated gas generation is far lower than the price of purchased electricity, resulting in significant savings in electricity costs. Product Sales Revenue: Associated gas can be processed and sold as commodities, such as CNG, LNG, LPG, or chemical feedstocks, creating new revenue streams. The commercialization of associated gas can generate substantial profits, particularly in regions with high natural gas market prices.

Carbon Emissions Trading: Reducing associated gas flaring reduces greenhouse gas emissions, helping companies obtain carbon emission quotas or participate in carbon trading markets, generating additional revenue. With the global goal of carbon neutrality, this has become a key way for companies to increase their value.

Enhanced Oil Recovery: Associated gas reinjection can increase reservoir recovery, extend field life, and increase crude oil production, generating long-term economic benefits.

Reduced Fines and Compliance Costs: Environmental penalties for associated gas venting or substandard emissions can be avoided, mitigating compliance risks.

Environmental Benefits:

Reduced Greenhouse Gas Emissions: Methane is a more potent greenhouse gas than carbon dioxide. Recycling associated gas, particularly as a fuel or chemical feedstock, can significantly reduce direct methane emissions into the atmosphere, thereby reducing the greenhouse effect and mitigating climate change. Improving regional air quality: Reducing the direct combustion or venting of associated gas can reduce emissions of pollutants such as carbon dioxide, sulfur compounds, and nitrogen oxides, improving air quality in areas surrounding oil fields and minimizing health impacts on local residents.

Conserving energy and resources: Associated gas is a valuable fossil energy resource. Recycling it embodies the principles of resource conservation and a circular economy, avoiding unnecessary energy waste.

Enhancing corporate social responsibility: Actively practicing associated gas recycling demonstrates oil and gas companies’ commitment to environmental protection, enhances their social responsibility and brand image, and helps win recognition and support from all sectors of society.

Promoting sustainable development: Associated gas recycling is a key initiative in the oil and gas industry’s transition to a green and low-carbon economy. It contributes to building a resource-saving and environmentally friendly society and promotes the sustainable development of the energy industry.

Cost Reduction and Efficiency Improvement Strategies: Critical Paths for Optimizing Oilfield Oil Well Gas CompressorSystems

Achieving cost reduction and efficiency improvement in associated gas recovery and utilization requires a comprehensive strategy encompassing the oilfield oil well gas compressor system, encompassing technology, management, and business models.

Optimizing System Design and Oilfield Oil Well Gas Compressor Selection:

Life Cycle Cost Analysis: At the initial project stage, a detailed economic assessment of the oilfield oil well gas compressor system is conducted, comprehensively considering initial investment, operating costs (energy consumption, maintenance), environmental benefits, and potential returns to select the optimal process route and equipment configuration.

Modular and Standardized Design: Modular, skid-mounted oilfield oil well gas compressor stations can significantly shorten construction cycles and reduce on-site construction costs. Standardized design also helps reduce spare parts inventory and maintenance complexity.

Refined Oilfield Oil Well Gas Compressor Selection: Based on the associated gas composition, pressure, flow rate, and ultimate utilization, the most efficient, reliable, and energy-efficient oilfield oil well gas compressor type and model is precisely selected to ensure optimal operation. For example, for high-pressure differential conditions, a multi-stage reciprocating compressor can be selected; for high-flow, low-pressure differential conditions, a centrifugal compressor may be more suitable.

Waste Heat Recovery: Utilize the exhaust gas waste heat or compression heat of the oilfield oil well gas compressor driver (such as a gas engine) for heating, drying, or other production processes, further improving overall energy efficiency.

Improving Operational Management:

Refine Operations: Establish a comprehensive operational management system and operating procedures for the oilfield oil well gas compressor system to ensure stable process parameters and reduce unplanned downtime.

Preventive and Predictive Maintenance: Regularly inspect, maintain, and repair oilfield oil well gas compressors and their auxiliary equipment. Introduce advanced condition monitoring technology to monitor parameters such as vibration, temperature, and pressure in real time. Use data analysis to predict equipment failures, implement predictive maintenance, and reduce unplanned downtime.

Energy-Saving and Consumption-Reducing Measures: Optimize the operating parameters of oilfield oil well gas compressors to avoid unnecessary venting and venting. Strengthen leak detection and repair in associated gas gathering and transportation pipelines. Promote variable frequency speed regulation technology to adjust the speed of oilfield oil well gas compressors based on actual load, achieving on-demand gas supply and minimizing energy consumption.

Innovative Technologies and Business Models:

Research and Application of Advanced Technologies: Continuously invest in the research and development of more efficient, environmentally friendly, and economical associated gas processing and utilization technologies, such as new separation membrane technology, high-efficiency desulfurizers, and distributed energy systems, to provide optimized integrated solutions for oilfield oil well gas compressor systems.

Diversified Utilization and Market Integration: Exploring diversified utilization models for associated gas based on the oilfield’s own needs and external market conditions. For example, collaborating with surrounding industrial parks to directly provide associated gas as fuel or feedstock; developing “oil and gas integration” projects to achieve synergistic development of associated gas and crude oil.

Market-Oriented Operations and Cooperation: Encourage the use of market-oriented methods in associated gas recovery and utilization projects, bringing in professional third-party companies for investment, construction, and operation. This will reduce the initial investment risk for oil and gas companies and leverage external expertise to enhance project profitability. Policy and Financial Support: Actively seek government policy support and financial subsidies for environmental protection and comprehensive energy utilization, leveraging tax incentives and special funds to reduce project investment and operating costs for oilfield gas compressor systems.

Digitalization and Intelligent Empowerment:

Industrial Internet Platform Construction: Build an industrial Internet platform for oil and gas field associated gas recovery and utilization, enabling data collection, transmission, storage, analysis, and visualization for key equipment such as oilfield gas compressors, providing data support for operational optimization, fault diagnosis, and scientific decision-making.

Big Data Analysis and Artificial Intelligence: Leverage big data analytics to mine historical operating data for oilfield gas compressors, identify patterns, and optimize process parameters. Introducing artificial intelligence algorithms for predictive maintenance, fault diagnosis, and intelligent scheduling will enhance the intelligence of system operations and ensure that oilfield gas compressors are always in optimal operating condition.

Application of Digital Twin Technology: Build a digital twin model of the associated gas recovery and utilization system, optimize the design through simulation, and conduct real-time monitoring, prediction, and optimal control during operation, enabling full lifecycle management of the entire system, including the oilfield gas compressors.

Conclusion

Oilfield gas compressors are the core of efficient associated gas recovery and utilization systems. Their performance and efficiency directly determine the economic and environmental benefits of these projects. In the face of increasingly severe energy and environmental challenges, by deeply understanding the characteristics of associated gas, mastering the advanced technical principles and selection of oilfield gas compressors, and actively applying modern pretreatment, gathering, transmission, and pressurization, and diversified utilization technologies, coupled with refined operational management, innovative business models, and digital and intelligent empowerment, oilfield companies can not only significantly reduce operating costs and improve economic efficiency, but also significantly reduce greenhouse gas emissions, improve environmental quality, and ultimately establish a green and sustainable corporate image.

Looking ahead, with increasingly stringent environmental regulations and the acceleration of global energy transition, the strategic position of oilfield gas compressors in the oil and gas industry will become increasingly prominent. We look forward to the emergence of more innovative technologies and collaborative models to jointly drive the global oil and gas industry towards greater efficiency, environmental protection, and sustainability, contributing significantly to achieving energy security and addressing climate change.