How to reduce the energy consumption of hydrogen compressors? Five optimization solutions help you save costs

Against the backdrop of increasing global energy shortages and increasing importance of environmental protection, energy consumption issues in industrial production have become the focus of corporate attention. Hydrogen, as a clean and efficient secondary energy source and important industrial raw material, plays an indispensable role in many fields such as chemical industry, metallurgy, electronics, and new energy. However, in the preparation, storage, transportation, and use of hydrogen, hydrogen compressors are one of the links with the highest energy consumption. Its high operating costs not only directly erode the profit margins of enterprises, but also run counter to the current global energy conservation, emission reduction, and sustainable development strategies that are actively promoted. Therefore, in-depth analysis of the deep-seated causes of hydrogen compressor energy consumption and systematically proposing a series of effective energy consumption optimization solutions have extremely far-reaching strategic significance for enhancing the core competitiveness of enterprises and achieving green and sustainable development.

The root cause of hydrogen compressor energy consumption

To effectively reduce energy consumption, it is first necessary to accurately identify the crux of excessive energy consumption. The energy consumption problem of hydrogen compressors is a complex multi-factor comprehensive result, and its main root causes can be attributed to the following points:

Low compression efficiency: This is one of the most core energy consumption problems. If the mechanical efficiency and volumetric efficiency of the compressor itself are not high, for example:

Design defects: There are unreasonable aspects in the design of the cylinder, piston, valve and other components of the compressor, resulting in large gas flow resistance and high dead volume ratio.

Internal leakage: Piston ring wear, loose valve closure, excessive clearance between the cylinder and the piston, aging or damage of the seal, etc., will cause gas leakage in the compression chamber, causing some compressed hydrogen to reflux or escape, resulting in ineffective power consumption.

Poor valve performance: The slow opening and closing response speed of the valve, deformation or wear of the valve plate will increase the resistance of gas passage, resulting in additional pressure loss and energy consumption.

Friction loss: The friction resistance between moving parts (such as pistons, connecting rods, bearings, etc.) is too large, consuming a lot of mechanical energy.

Improper temperature control: The compression process is essentially a process of gas work and temperature increase.

Thermodynamic properties: Hydrogen releases a large amount of heat during the compression process. If this heat cannot be taken away in time and effectively, the gas temperature will continue to rise.

Increased compression work: According to the gas law, the higher the gas temperature, the lower its density, and the same mass of gas requires a larger volume at the same pressure. In order to reach the predetermined pressure, the compressor needs to do more work to compress the high-temperature gas, resulting in increased energy consumption.

Inefficient cooling system: Cooler scaling, blockage, insufficient cooling medium flow or excessive temperature will reduce the cooling effect, causing the compressor to continue to operate at high temperature.

Gas purity and impurity effects: The purity of hydrogen has a direct impact on the operating efficiency and life of the compressor.

Solid particles: Dust, rust, welding slag and other solid particles carried in hydrogen will enter the compressor, causing wear of moving parts such as pistons, cylinders, and valves, accelerating equipment aging, resulting in poor sealing and reduced efficiency.

Liquid water and oil mist: Water may condense into liquid water during the compression process, while oil mist comes from the lubrication system. They will adhere to the inner wall of the gas valve and pipeline, increase the gas flow resistance, and even mix with hydrogen to form foam, affecting the compression efficiency. In the long run, it will also corrode the equipment and shorten the service life.

Other gas impurities: Non-hydrogen components such as nitrogen and oxygen mixed in will change the compression characteristics of the mixed gas and increase the load of the compressor.

Equipment aging and insufficient maintenance: Any mechanical equipment will wear and age in the long run.

Component wear: Key components such as piston rings, bearings, seals, and gas valves wear with the increase of running time, and the performance gradually decreases.

Seal failure: Aging seals lose elasticity, causing gas leakage and reducing volumetric efficiency.

Poor lubrication: Deterioration of lubricating oil, insufficient oil or excessive impurities will increase friction, aggravate component wear, and increase energy consumption.

Lack of maintenance: Failure to perform regular inspections, cleaning, tightening and replacement of wear parts according to the manufacturer’s recommendations will cause the performance of the equipment to gradually decline until failure occurs, resulting in high maintenance costs and production stagnation.

Mismatched operating modes: The compressor does not always operate under the designed operating conditions.

Frequent start and stop: The compressor needs to overcome huge inertia every time it starts, and the instantaneous current and power consumption will be very large. Frequent start and stop will cause a lot of energy waste and accelerate equipment wear.

Large load fluctuations: When the gas consumption fluctuates greatly, if the compressor cannot flexibly adjust the output, “empty” or “pressure holding” phenomena may occur. For example, at low load, the compressor may still run at full speed and maintain pressure by unloading (discharging compressed gas back to the suction port), but this will consume a lot of no-load power.

Non-rated operating conditions: The compressor is designed with an optimal efficiency operating range. When the actual operating pressure, temperature, flow, etc. deviate from the design value, its efficiency will drop significantly.

Limitations of traditional drive technology: Most traditional compressors are driven by fixed-speed motors.

Fixed speed: Fixed-speed motors can only run at a constant speed, which means that the exhaust volume of the compressor is fixed.

“On/off” or “load/unload” control: When the gas consumption is less than the exhaust volume, the compressor can only maintain pressure through frequent loading/unloading cycles, or discharge excess gas through the vent valve, which will cause significant energy waste.

Unable to accurately match demand: This inflexible control method cannot be accurately adjusted according to the actual hydrogen demand for production, resulting in a large amount of energy consumption.

Optimization plan 1: Improve the efficiency of the compressor

Improving the efficiency of the compressor itself is the fundamental way to reduce energy consumption, which requires refined management at multiple levels such as equipment selection, design improvement and daily maintenance:

Choose an efficient compressor type:

In-depth assessment of needs: When purchasing new equipment, the most suitable compressor type should be comprehensively evaluated and selected based on the actual gas consumption, pressure, purity requirements, operating time, environmental conditions and investment budget.

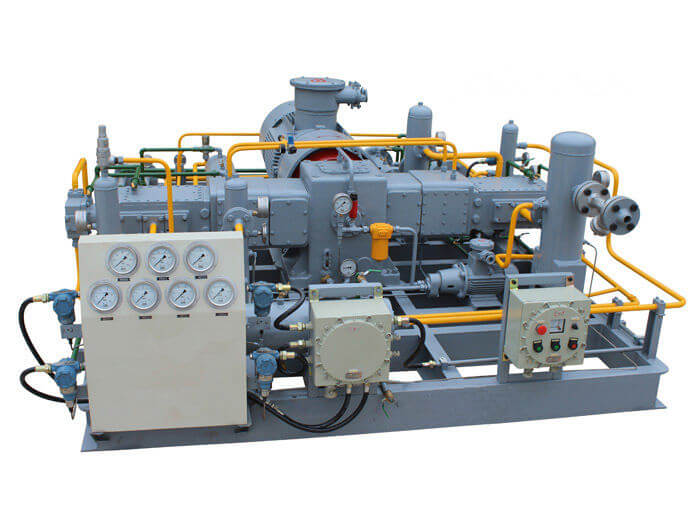

Comparison of technical routes: The mainstream hydrogen compressors on the market currently include reciprocating (piston), centrifugal and screw.

Reciprocating compressor: Suitable for high-pressure and small-flow occasions, its efficiency is usually high, but the vibration and noise are relatively large, and more frequent maintenance is required. High-efficiency piston machines with new valve sheet materials (such as PEEK), optimized cylinder structure, and improved lubrication system should be selected.

Centrifugal compressors: Suitable for large flow and low pressure occasions, stable operation, and relatively low maintenance costs. Key parameters such as impeller design and diffuser efficiency should be paid attention to.

Screw compressors: Suitable for medium flow and pressure, relatively stable operation, and high reliability. Screw machines with optimized rotor profiles, precise clearance control, and small internal leakage should be selected.

Pay attention to energy efficiency indicators: When comparing compressors of different brands and models, focus on key energy efficiency indicators such as specific power (power consumption per unit flow, kW/m³/min), isothermal efficiency or adiabatic efficiency. Products with energy efficiency certification (such as national first-level energy efficiency standards) are preferred.

Optimize compressor design and operating parameters:

Improvement of valve structure: Traditional metal valves have slow response and short life. Consider replacing with high-performance composite material (such as PEEK) valves, annular valves or labyrinth valves. These new valves have the advantages of light weight, fast response, good sealing, wear resistance, and long life. They can effectively reduce airflow resistance and improve charging and exhaust efficiency.

Flow channel optimization: Improve the design of the air flow channel inside the compressor, reduce turns and mutations, make the air flow smoother, reduce gas flow resistance, and thus reduce pressure loss and energy consumption. For example, optimize the design of the air inlet, exhaust port, valve cavity, etc.

Dead volume ratio optimization: Dead volume refers to the space between the top surface of the piston and the cylinder head when the cylinder piston reaches the end of the stroke. Excessive dead volume will cause gas expansion and reduce volumetric efficiency. Through precise processing and assembly, the dead volume can be reduced as much as possible to increase the effective volume of the compressor.

Accurately control the interstage pressure: For multi-stage compressors, the reasonable distribution of compression ratios at each stage is crucial. If the pressure distribution of a certain stage is unreasonable, it may cause the compressor of that stage to be overloaded or inefficient. Through precise calculation and adjustment, all compressors at each level can work near their optimal compression ratio to maximize overall efficiency. For example, pressure sensors can be used to monitor interstage pressure in real time and fine-tune it in combination with the control system.

Reduce internal leakage:

Regularly check and replace seals: Piston rings, stuffing box seals, valve plate seals, O-rings, etc. are key sealing components inside the compressor. These components will gradually wear or age during use, resulting in seal failure. According to the equipment manufacturer’s maintenance manual, the wear should be checked regularly, and the severely worn parts should be replaced in time to ensure good sealing.

Precision machining and assembly: During the manufacturing and maintenance of the compressor, ensure the machining accuracy of the matching parts such as the cylinder, piston, and valve seat, as well as the assembly quality, reduce the matching clearance, and thus reduce the possibility of gas leakage.

Use high-performance lubricants: In addition to lubrication, lubricating oil can also play a certain sealing role. Selecting special compressor lubricating oil with suitable viscosity, good sealing, and non-volatile can help reduce internal leakage.

Reduce friction loss:

Optimize the lubrication system: Ensure that the lubrication system works properly, the lubricating oil is sufficient and of good quality. Selecting the appropriate lubricating oil viscosity should ensure the lubrication effect while avoiding excessive viscosity that increases friction resistance.

Bearing and piston rod maintenance: Regularly check and replace worn bearings and piston rods to ensure smooth operation and reduce friction.

Component surface treatment: Perform surface strengthening treatment on key moving parts (such as cylinder inner wall and piston surface), such as plating, nitriding, etc., to improve their wear resistance and reduce friction coefficient.

Optimization plan 2: temperature control and cooling system optimization

Effective temperature control is a key link to ensure efficient operation of hydrogen compressors and reduce energy consumption, because high temperature will directly increase compression work and wear.

Optimize cooling medium and flow:

Medium selection: Select the most suitable cooling medium according to the compressor type, cooling method (water cooling or air cooling) and environmental conditions. For large or high-pressure compressors, water cooling is usually used, and it is necessary to ensure that the water quality meets the requirements to prevent scaling and corrosion. For small or mobile compressors, air cooling is more common, but the ambient temperature and heat dissipation efficiency must be considered.

Precise flow control: Too low cooling medium flow will lead to poor cooling effect and temperature rise; too high flow will waste energy (pump energy consumption). Therefore, according to the compressor operating load and ambient temperature, the flow of the cooling medium should be accurately controlled by installing a regulating valve or a variable frequency pump to keep it at the minimum flow level required for the best cooling effect.

Inlet temperature control: Ensure that the inlet temperature of the cooling medium is within a reasonable range. Too high an inlet temperature will reduce the cooling efficiency. Precooling the cooling medium can be considered, such as through a cooling tower, a chiller, or using the low temperature environment in winter.

Improve cooler design and maintenance:

High-efficiency heat exchanger: New high-efficiency heat exchangers with higher heat transfer coefficients, larger heat transfer areas, and more compact structures are preferred, such as plate heat exchangers, fin-tube heat exchangers, etc., to maximize the removal of compression heat.

Structural optimization: Optimize the flow channel design of the cooler, reduce fluid resistance, avoid dead corners, and improve fluid uniformity, thereby enhancing heat exchange efficiency.

Anti-scaling and anti-corrosion: For water cooling systems, the cooling water should be treated regularly, and corrosion inhibitors and scale inhibitors should be added to prevent scaling, corrosion or microbial growth inside the cooler, which will seriously affect the heat exchange efficiency and increase energy consumption.

Regular cleaning and maintenance: Regularly mechanically or chemically clean the cooler to remove dust, oil, scale, etc. accumulated on the heat exchange surface to restore its optimal heat exchange performance. Check the working status of the cooling fan or water pump to ensure its efficient operation.

Utilize waste heat recovery:

Energy recycling: Hydrogen compressors generate a lot of heat energy during the compression process, which is usually dissipated into the environment through the cooling system, causing energy waste. Through waste heat recovery technology, this part of heat energy can be effectively utilized, thereby improving the overall energy utilization efficiency.

Recycling application scenarios:

Preheating feed hydrogen: The recovered heat energy can be used to preheat the hydrogen entering the compressor, thereby reducing the compressor inlet temperature and reducing compression work.

Production of domestic hot water: Convert waste heat into hot water for production process water, winter heating or employee living water.

Driving other equipment: In some cases, the recovered waste heat can even drive an absorption chiller or thermal expander to generate cooling or electricity.

Drying or heating process: Use waste heat in industrial production processes that require heating or drying.

Heat recovery equipment: Plate heat exchangers, fin-tube heat exchangers or integrated heat recovery modules can be installed to collect and utilize waste heat.

Intelligent temperature control system:

Real-time monitoring and data analysis: Introduce advanced temperature sensors and data acquisition systems to monitor key parameters such as compressor exhaust temperature at all levels, bearing temperature, and cooling medium inlet and outlet temperature in real time. By analyzing these data, temperature anomalies can be detected in time to determine whether there is insufficient cooling or internal faults.

Adaptive control: Based on real-time temperature data and preset optimization algorithms, the intelligent temperature control system can automatically adjust the flow rate of the cooling medium, the speed of the cooling fan or the frequency of the water pump. For example, when the exhaust temperature rises, the system automatically increases the cooling medium flow rate or the fan speed to ensure that the compressor always operates within the optimal temperature range.

Interlock protection: Set high temperature alarm and automatic shutdown protection. When the temperature exceeds the safety threshold, the alarm will be issued in time and the machine will be automatically shut down to prevent the equipment from being damaged due to overheating and ensure production safety.

Remote monitoring and diagnosis: Combined with the Internet of Things technology, remote monitoring and diagnosis of the cooling system can be achieved, which makes it convenient for managers to grasp the operating status of the equipment at any time and perform remote troubleshooting.

Optimization plan 3: gas treatment and filtration technology

The impurities in hydrogen will not only accelerate the wear of compressor parts and reduce their operating efficiency, but also may cause safety hazards and product quality problems. Therefore, efficient gas treatment and filtration are the key to ensuring the stable and efficient operation of the compressor.

Efficient pretreatment:

Multi-stage purification concept: Before hydrogen enters the compressor, a multi-stage gas pretreatment system should be designed to remove various impurities to the maximum extent.

Dust removal: For hydrogen coming out of processes such as electrolyzers or steam reforming, it may contain tiny particles. A pre-filter, such as a cyclone separator, bag filter or primary filter, should be set to remove large suspended particles.

Dehydration: The moisture carried in hydrogen is the main cause of corrosion, ice blockage and compression efficiency. Adsorption dryers (such as pressure swing adsorption PSA, temperature swing adsorption TSA), freeze dryers or membrane separation technology can be used to reduce the water dew point in hydrogen to below the compressor requirements. Especially for high-temperature and high-pressure hydrogen, the water vapor content will be higher, and dehydration is particularly important.

De-oiling: If the upstream process or the compressor itself (such as an oil-lubricated compressor) produces oil mist, the hydrogen must be de-oiled before entering the compressor to prevent oil from adhering to valves, pipes and equipment, affecting efficiency and life. Coalescing filters or activated carbon adsorbers can be used to effectively remove oil mist.

Other impurity removal: Depending on the source and purpose of hydrogen, other harmful impurities such as sulfides (desulfurization), chlorides, and carbon dioxide may also need to be removed to protect the compressor and subsequent process equipment.

Select high-performance filters:

Fine filtration: After pretreatment, the hydrogen before entering the compressor also needs to pass through a high-performance fine filter. These filters should be able to effectively remove micron-level solid particles and submicron-level oil mist to ensure that the hydrogen entering the compressor is highly pure.

Filter material selection: Select appropriate filter materials such as glass fiber, polypropylene, PTFE, etc. according to the filtration accuracy and medium characteristics to ensure that the filter material has no adsorption and no pollution to hydrogen.

Filter element structure: Choose a filter element structure with large surface area, high dust holding capacity and low pressure drop, such as folded, wound or sintered, to extend the service life of the filter element and reduce operating energy consumption.

Differential pressure monitoring: Install a differential pressure gauge before and after the filter to monitor the pressure drop of the filter element in real time. When the pressure drop reaches the set value, it indicates that the filter element is blocked and needs to be replaced in time.

Online monitoring and early warning:

Hydrogen purity analysis: Install an online hydrogen purity analyzer to monitor the purity of hydrogen entering the compressor in real time. Once the purity drops or the impurity content exceeds the standard, the alarm mechanism is immediately activated and the cause is traced to prevent unqualified hydrogen from entering the system.

Dew point meter: Install an online dew point meter before hydrogen enters the compressor to monitor the moisture content in hydrogen in real time to ensure that it meets the compressor operation requirements.

Oil content analyzer: For oil-free compressors or systems with strict requirements on oil content, an online oil content analyzer can be installed to ensure that the oil mist content in hydrogen is controlled at an extremely low level.

Early warning mechanism: connect these monitoring data with the central control system. Once any key indicator exceeds the set range, the system automatically issues an audible and visual alarm and notifies the operator by SMS or email so that timely intervention measures can be taken to avoid potential equipment damage and production accidents.

Circulation purification system:

Closed-loop process considerations: In some hydrogen application scenarios, such as fuel cell testing, hydrogen circulation reactors, etc., hydrogen will be recycled. In such a closed-loop system, impurities (such as water vapor, oil mist, reaction by-products) will gradually accumulate as the cycle proceeds.

Bypass purification: To ensure the purity of the circulating hydrogen, a bypass purification device can be set on the circulation pipeline. This system can continuously extract a portion of the circulating hydrogen, perform fine dehydration, deoiling and impurity removal, and then return the purified hydrogen to the circulation system.

Reduce cumulative load: Through circulation purification, the accumulation of impurities in the system can be effectively controlled, thereby significantly reducing the load of the hydrogen compressor, reducing the wear and energy consumption caused by impurities, and at the same time ensuring the requirements of the subsequent process or equipment for the purity of hydrogen. This not only protects the compressor, but also extends the service life of the entire system.

Optimization Plan 4: Regular Maintenance and Intelligent Monitoring

The concept of “prevention is better than cure” is particularly important in the operation and maintenance of hydrogen compressors. Establishing a complete maintenance system and combining it with advanced intelligent monitoring technology is the key to ensuring long-term efficient and stable operation of equipment and minimizing energy consumption.

Establish a complete maintenance plan:

The core of preventive maintenance: Based on the recommendations of equipment manufacturers, operating experience and industry best practices, formulate a detailed and periodic preventive maintenance plan.

Daily inspection: Visually and auditorily inspect the appearance, operating sound, vibration, temperature, pressure, oil level, leakage points, etc. of the compressor every day or every shift, and record the operating parameters.

Regular maintenance:

Weekly/monthly: Check and tighten the connectors, clean the filter, check the lubrication system, and remove condensate.

Quarterly/half yearly: Check the wear of the valve, piston ring, stuffing box, and bearing, replace the air filter and oil filter, and test the oil quality.

Every year/overhaul cycle: Carry out a thorough overhaul or medium overhaul, conduct a comprehensive inspection of key components, replace wear parts, calibrate instruments, clean the inner and outer surfaces of the cooler, check the insulation of the motor, etc.

Fault shutdown maintenance: For each unplanned shutdown or failure, record the fault phenomenon, cause analysis, treatment process and preventive measures in detail to form a fault database to provide a reference for subsequent maintenance.

Spare parts management: Establish a reasonable spare parts inventory to ensure the timely supply of key wearing parts and commonly used spare parts to avoid long downtime due to spare parts shortage.

Condition monitoring and fault diagnosis:

Multi-parameter sensor application: Deploy various sensors to collect compressor operation data in real time and continuously.

Vibration sensor: Monitor the vibration characteristics of compressor bearings, gears, pistons and other components. Abnormal vibration is often an early signal of bearing wear, loose or misaligned components.

Temperature sensor: Monitor exhaust temperature at all levels, bearing temperature, motor temperature, cooling water/oil temperature, etc. Abnormal temperature rise is a manifestation of increased friction, poor cooling or overload.

Pressure sensor: monitors suction pressure, exhaust pressure, interstage pressure, lubricating oil pressure, etc. Abnormal pressure may indicate valve failure, leakage or pipeline blockage.

Flow sensor: monitors hydrogen inlet and outlet flow and cooling medium flow, and evaluates compressor efficiency and cooling effect.

Current/voltage sensor: monitors motor operating current and voltage, and analyzes motor load and energy consumption.

Data acquisition and transmission: transmits the data collected by the sensor to the central control room or data server through wired or wireless networks.

Fault diagnosis system: uses advanced signal processing and pattern recognition technology to analyze the collected data in real time. Combined with artificial intelligence (AI) and machine learning algorithms, establish equipment health models, predict potential faults, perform trend analysis, and provide specific fault diagnosis suggestions. For example, through vibration spectrum analysis, specific bearing damage or gear defects can be identified.

Predictive maintenance: Based on the results of condition monitoring and fault diagnosis, the traditional “periodic maintenance” is transformed into “predictive maintenance”. That is, no longer relying solely on fixed cycles, but based on the actual operating status and health trends of the equipment, targeted maintenance is carried out before the failure occurs, minimizing unplanned downtime and extending component life.

Oil management:

The importance of lubricating oil: Lubricating oil not only plays the role of lubrication, cooling and sealing in the compressor, but also cleans the equipment. Its quality directly affects the operating efficiency, energy consumption and life of the compressor.

Regular oil sample analysis: Lubricating oil samples are taken regularly and sent to professional laboratories for analysis. The test items include:

Viscosity: Determine whether the oil is oxidized or contaminated.

Acid value: Reflects the degree of aging and corrosiveness of the oil.

Water content: Assess whether there is water intrusion.

Particle content: Monitor wear particles and determine the wear of components.

Metal element content: Analyze the type and concentration of wear metal elements (such as iron, copper, aluminum, etc.) to predict the degree of wear of specific components (such as bearings and piston rings).

Replacement based on analysis results: Decide whether to replace lubricating oil or perform oil treatment based on the results of oil sample analysis rather than a simple time period to ensure that the lubricating oil is always in the best condition, reduce friction loss, and extend the life of the equipment.

Oil storage and addition: Ensure that the storage environment of lubricating oil is clean and dry to avoid contamination. When adding or replacing lubricants, follow the correct operating procedures to avoid introducing impurities.

Remote intelligent monitoring system:

Internet of Things (IoT) platform: Build an intelligent monitoring platform based on IoT technology to centralize the operating data of all compressors worldwide to the cloud for management.

Data visualization and dashboard: Through an intuitive graphical interface and customized dashboard, the operating status, key parameters, historical trends and alarm information of the equipment are displayed in real time. Managers can view it anytime and anywhere through a computer or mobile device.

Big data analysis and AI empowerment: Use big data analysis technology to explore the laws behind massive operating data and identify abnormal patterns. Combined with artificial intelligence algorithms, evaluate the health status of the equipment, predict the possibility and time of future failures, and give suggestions for optimizing operation and maintenance.

Remote diagnosis and optimization: The expert team can remotely diagnose equipment problems based on remote monitoring data and guide on-site personnel to troubleshoot. Some operating parameters can even be optimized and adjusted through remote control.

Predictive maintenance (advanced): AI-based predictive maintenance can be accurate to the component level and warn of component failures weeks or months in advance, allowing companies to have sufficient time to schedule downtime, purchase spare parts and perform maintenance, turning unplanned downtime into planned downtime and minimizing production losses.

Optimization Plan 5: Use variable frequency drive technology

Variable frequency drive technology is a revolutionary breakthrough in the field of hydrogen compressor energy consumption management. It achieves flexible adjustment of compressor output by precisely controlling the motor speed, thereby significantly improving energy efficiency.

Supply gas on demand and eliminate no-load waste:

Limitations of traditional fixed speed mode: Traditional hydrogen compressors are usually directly driven by industrial frequency motors with fixed speed. When the demand for hydrogen fluctuates during the production process (which is the norm in industrial production), fixed-speed compressors cannot adjust their exhaust volume in real time. When the actual gas consumption is lower than the rated exhaust volume of the compressor, in order to maintain the system pressure, the compressor has to frequently enter the “load/unload” cycle. In the unloaded state, although the compressor does not supply gas to the system, the motor is still idling at high speed. The power consumed by this part of no-load operation (usually accounting for 20%-40% of the full-load power consumption) is a pure waste.

The core advantage of the frequency converter: The frequency converter (VFD) can smoothly adjust the speed of the motor by changing the power frequency and voltage supplied to the motor. When the demand for hydrogen decreases, the inverter will reduce the motor speed, thereby reducing the exhaust volume of the compressor, so that its output is accurately matched to the actual demand. This means that the compressor can run at “full load” for a long time (although it is full load at low speed), avoiding frequent unloading and idling, thereby significantly reducing no-load energy consumption.

Actual benefits: For working conditions with large fluctuations in gas consumption, variable frequency drive technology can usually bring 20% to 50% energy savings, and the return on investment period is short.

Stabilize pressure control and improve process accuracy:

Traditional control hysteresis: Traditional compressor pressure control is usually “on/off” control, that is, when the system pressure is lower than the set lower limit, it starts, and when it is higher than the set upper limit, it unloads or stops. This control method will cause the system pressure to fluctuate within a certain range, affecting the stability of subsequent processes.

Precise adjustment of the inverter: The inverter can achieve PID (proportional-integral-differential) closed-loop control of the compressor outlet pressure. By monitoring the system pressure in real time, the inverter can quickly adjust the motor speed to keep the pressure near the set target value, and the pressure fluctuation range can usually be controlled within ±0.1 bar or even smaller.

Process optimization: Stable gas supply pressure can not only avoid the impact of pressure fluctuations on downstream equipment (such as reactors, hydrogen fuel cells), improve product quality and production efficiency, but also set the system pressure to the minimum value that meets the process requirements, further saving energy. Because every 0.1 bar reduction in exhaust pressure can usually save about 1% of energy consumption.

Soft start and reduce impact, extend equipment life:

Traditional start-up impact: Traditional fixed-speed motors will generate a starting current of up to 5-7 times the rated current when starting, which will cause a huge impact on the power grid, may cause a sudden drop in voltage, and affect the normal operation of other equipment. At the same time, the instantaneous mechanical impact will also accelerate the wear of motor windings, bearings and compressor mechanical parts, shortening the life of the equipment.

Flexible start of the inverter: The inverter has a soft start function. At startup, the inverter will gradually increase the output frequency and voltage to smoothly accelerate the motor from zero speed to the set speed. The starting current can be controlled within 1.5 times of the rated current.

Multiple benefits: Soft start not only significantly reduces the impact on the power grid (avoiding the potential cost of increasing the capacity of the distribution system), but also greatly reduces the wear of mechanical parts and extends the mechanical life and maintenance cycle of the compressor (especially the piston machine). In addition, the smooth start-stop process also reduces noise and improves the working environment.

Reduce peak current: Through soft start, you can avoid high peak current fines and reduce electricity bills.

Adapt to complex working conditions and optimize control:

Strong adaptability: The variable frequency drive system can better adapt to changes in working conditions such as inlet pressure and temperature, and maintain the best operating state by automatically adjusting the speed.

Multi-machine joint control: For systems with multiple hydrogen compressors, variable frequency technology can be used to achieve multi-machine joint control. Through intelligent control strategies, the system can automatically select the best compressor combination (the combination of variable frequency machine and industrial frequency machine, or the coordination of multiple variable frequency machines) according to the total gas consumption to minimize overall energy consumption. For example, the inverter can be started first to meet the basic load, and when the demand increases, the industrial frequency machine can be started and fine-tuned by the inverter.

Energy management system integration: The inverter usually has a rich communication interface, which can be easily integrated with the factory’s energy management system (EMS) or DCS system to achieve real-time monitoring, data analysis and remote optimization of the compressor energy consumption.

Energy saving potential mining: The inverter itself has advanced control algorithms, such as flux vector control, which can maximize the operating efficiency of the motor and further explore the energy saving potential.

Conclusion

Reducing the energy consumption of hydrogen compressors is not a problem that can be solved by a single technology or measure. It is a comprehensive project involving equipment selection, system design, operation management, maintenance and technology upgrades. By thoughtfully implementing the five optimization solutions described in this article – selecting and optimizing high-efficiency compressors, refining temperature control and cooling systems, strictly implementing gas treatment and filtration, establishing a sound regular maintenance and intelligent monitoring system, and innovatively introducing variable frequency drive technology – enterprises will be able to systematically improve the overall energy efficiency of hydrogen compressors.

This not only means direct economic benefits, such as significantly reduced electricity bills and maintenance costs, but more importantly, it will bring more far-reaching strategic value to enterprises: improving the stability and safety of the production process, extending the service life of equipment, and reducing carbon emissions, thereby comprehensively enhancing the market competitiveness and sustainable development capabilities of enterprises. In the current context of global green transformation, the continuous exploration and application of more advanced energy efficiency optimization technologies will be an important driving force for the hydrogen energy industry and even the entire industrial field to achieve high-quality and sustainable development.