LPG compressor is noisy and inefficient? 5 optimization solutions to solve it quickly!

-3.png)

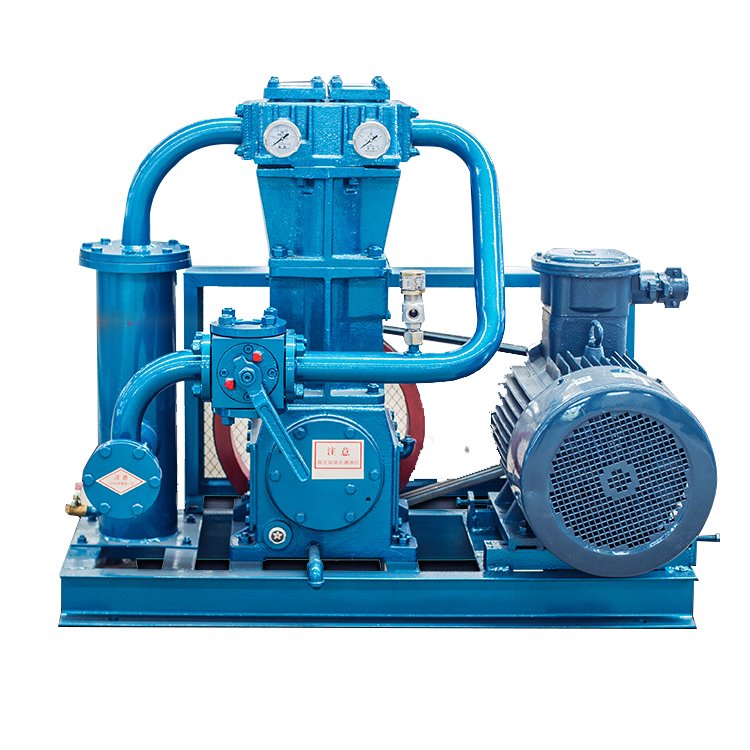

In modern industrial production, liquefied petroleum gas (LPG), as a clean and efficient energy source, plays an irreplaceable role in many fields such as petrochemicals, gas supply, metallurgy, and ceramics. As the core equipment in the LPG system, the performance of LPG compressors is directly related to production efficiency, energy consumption and even the economic benefits of enterprises. However, many companies have long faced the dual problems of excessive noise and low efficiency during the operation of LPG compressors. Noise not only harms the health of employees and deteriorates the working environment, but is also likely to violate environmental protection regulations; while low efficiency means huge energy waste and high operating costs. How to effectively solve these “chronic diseases” of LPG compressors and improve their overall operating efficiency has become a key issue that many LPG-using companies need to solve urgently. This article will start with the working principle and common problems of LPG compressors, deeply analyze the hazards of noise and low efficiency, and on this basis, elaborate and provide you with 5 practical optimization solutions, aiming to help companies quickly and effectively solve the noise and efficiency problems of LPG compressors and achieve comprehensive improvement of equipment performance.

Working principle and common problems of LPG compressors

-3.png)

LPG compressors are key equipment that use mechanical energy to work on LPG gas, reducing its volume and increasing its pressure, thereby meeting storage, transportation or process requirements. According to their compression methods and structural characteristics, common LPG compressors mainly include piston type, screw type and centrifugal type. Understanding their respective working principles and common problems is the prerequisite for effective optimization.

Piston compressor:

Working principle: Piston LPG compressor is one of the earliest widely used compressor types. Its working principle is similar to the piston movement of a car engine: the piston is driven to reciprocate in a closed cylinder through a crank-connecting rod mechanism. When the piston moves downward, the suction valve opens and LPG gas is sucked into the cylinder; when the piston moves upward, the suction valve closes, the exhaust valve opens, and the gas is compressed and discharged. This process is intermittent, forming a cycle of suction, compression and exhaust.

Advantages: The structure is relatively simple, the manufacturing and maintenance costs are low, the purity of LPG gas is not high, and it is suitable for a variety of working conditions, especially for small and medium flow and high pressure occasions.

Common problems:

Noise and vibration: Due to the reciprocating motion of the piston and the frequent opening and closing of the valve, the piston compressor will generate large mechanical impact noise and vibration during operation, especially when running at high speed. Air flow pulsation also contributes significantly to noise.

Efficiency problem: The wear of seals such as piston rings and valve plates will cause gas leakage and reduce compression efficiency. In addition, there is pressure loss when the valve is opened and closed, which will also affect the overall efficiency.

Many vulnerable parts: Piston rings, air valves, bearings, etc. are vulnerable parts that need to be inspected and replaced regularly, increasing the maintenance workload.

Heat generation: The compression process generates a lot of heat. If the cooling system is insufficient, it may cause the body temperature to be too high.

Working principle: The screw LPG compressor is mainly composed of a pair of intermeshing spiral rotors (male rotor and female rotor). During operation, LPG gas enters the suction end of the screw rotor. As the rotor rotates, the gas is sucked into the volume between the rotor teeth and moves along the axial direction of the rotor. As the rotor continues to rotate, the volume between the rotor teeth gradually decreases, the gas is compressed, and finally discharged from the exhaust end. This compression process is continuous and smooth.

Advantages: Smooth operation, low vibration, relatively low noise; no reciprocating parts, few moving parts, high reliability, long service life; LPG gas has no oil contact (dry screw) or oil and gas are separated after mixing (oil-injected screw), and the gas cleanliness is high. Suitable for large and medium flow occasions.

Common problems:

High initial investment: The precision-machined screw rotor and complex oil circulation system lead to high manufacturing costs.

Requirements for LPG gas purity: Although there is filter protection, if the LPG gas contains more impurities, especially solid particles, it may cause screw rotor wear and affect performance.

Oil system: Oil-injected screw compressors require an efficient oil-gas separation system. If the separation is not thorough, LPG gas may be oily.

Seal wear: The gap between the screw rotor and the casing needs to be kept precise. Bearing wear or rotor deformation will affect the seal and reduce efficiency.

Centrifugal compressor:

Working principle: The centrifugal LPG compressor mainly relies on the high-speed rotating impeller to make the LPG gas obtain kinetic energy through the centrifugal force, and then convert the kinetic energy into pressure energy. LPG gas is sucked from the center of the impeller, and driven by the high-speed rotation of the impeller, it is thrown out radially. When passing through the diffuser, the gas flow rate decreases and the pressure increases. This process is continuous.

Advantages: Large flow, suitable for large-scale LPG storage or transportation systems; compact structure, small footprint; smooth operation, no pulsation; no internal lubrication, high LPG gas cleanliness.

Common problems:

Surge phenomenon: Under low flow or high pressure difference conditions, centrifugal compressors may surge, causing severe vibration of the equipment and performance degradation.

Sensitive to gas source fluctuations: It is sensitive to LPG gas flow and pressure fluctuations. If the fluctuation is too large, it may cause unstable operation.

Complex startup: The startup process requires precise control to avoid surge.

High manufacturing cost: The high-speed rotating precision impeller and bearing system make the manufacturing cost high.

Common common problems:

In addition to their own characteristics, all types of LPG compressors may face some common problems, which are the root causes of noise and inefficiency:

Seal failure: Whether it is the piston ring, valve plate, shaft seal or the gap between the screws, any form of seal failure will cause gas leakage, which will directly reduce the compression efficiency.

Friction and wear: Friction between moving parts is inevitable, but if the lubrication is poor, the parts are severely worn or the matching clearance is improper, it will cause additional energy loss and generate noise.

Vibration and imbalance: Unbalanced component manufacturing, unstable installation foundation, insufficient pipeline support or system resonance may cause severe vibration, which will cause noise and accelerate equipment damage.

Insufficient cooling: The compression process generates heat. If the cooling system is inefficient, it will cause the gas temperature to rise, reduce the compression efficiency, and may damage the equipment components.

Poor lubrication: Problems in any link such as the quality of the lubricating oil, the oil level, the circulation system, etc. may lead to increased friction and poor heat dissipation, affecting the life and efficiency of the equipment.

Foreign matter and scaling: Impurities in the LPG gas or scaling in the system may block the pipeline, damage the valve and compression elements, and affect normal operation.

Improper operation: Overload operation, incorrect start-stop procedures, unreasonable operating parameter settings, etc. will accelerate equipment loss and reduce efficiency.

Hazards of high noise and low efficiency

Noise and low efficiency in LPG compressor operation are by no means small problems. They are interrelated and together constitute multiple negative impacts on enterprise production, employee health and even the social environment.

Noise hazards:

Threat to employee health: Long-term exposure to industrial noise environments exceeding 85 decibels may cause a series of health problems for employees. The most direct impact is hearing damage, including temporary hearing threshold shift and permanent hearing loss, and severe cases may even lead to occupational deafness. In addition, noise can also cause nervous system disorders, manifested as headaches, insomnia, inattention, irritability, increased mental stress, etc., and long-term accumulation may even induce cardiovascular diseases. High noise environments are also prone to employee fatigue, reduced alertness, and increased risk of operational errors.

Impact on the production environment: Noise interference makes it difficult for employees to concentrate and communication is difficult, which can easily lead to operational errors and production accidents. High noise also affects the normal operation of precision equipment, which may cause measurement errors or equipment failures. A bad working environment will also reduce employees’ job satisfaction and production enthusiasm, increase staff turnover, and bring additional human resource costs to the company.

Violation of environmental regulations: Many countries and regions have strict legal and regulatory restrictions on industrial noise emissions. If the noise of LPG compressors exceeds the standard, the company will face fines, rectification within a time limit, or even administrative penalties such as suspension of production from the environmental protection department, which will seriously affect the normal operation and reputation of the company.

Damage to corporate image: Noise pollution not only affects internal employees, but may also cause harassment to residents in the surrounding communities. If not handled properly, it may trigger community complaints and media attention, damage the company’s social responsibility image, and affect the harmonious relationship between the company and the community.

Hazards of inefficiency:

Soaring energy costs: Compressors are energy consumers, and their efficiency directly determines the amount of energy consumed. An inefficient LPG compressor means that more electricity or fuel is needed to complete the established LPG gas compression volume. This will undoubtedly cause the company’s energy bill to rise sharply. With energy prices rising today, this additional expenditure will significantly erode the company’s profit margins. Long-term accumulated energy waste will be a huge hidden cost for the company.

High operating and maintenance costs: Low efficiency is often accompanied by deterioration of equipment operating conditions, such as increased friction, temperature, and vibration. These factors accelerate the wear and aging of parts, such as bearings, piston rings, valve plates, seals, etc., resulting in higher equipment failure rates and increased maintenance frequency. Frequent maintenance not only generates direct maintenance costs (spare parts, labor), but more importantly, leads to production line shutdowns, resulting in huge indirect economic losses. The shortened equipment life also means that companies need to update equipment more frequently and increase fixed asset investment.

Limited production capacity: Reduced compressor efficiency means that the amount of LPG gas provided per unit time is reduced, or the required pressure and flow cannot be achieved. This may cause downstream production lines to be unable to operate at full capacity due to insufficient LPG supply, or even be forced to stop production, directly affecting the company’s overall production capacity and order delivery. In an environment of fierce market competition, a decline in production capacity may lead to a loss of market share.

Increased environmental load: More energy consumption usually means more carbon emissions and other pollutant emissions, which runs counter to the current global advocacy of energy conservation, emission reduction, and green development concepts. If companies fail to meet environmental standards, they may also face government penalties and have a negative impact on their sustainable development.

5 optimization solutions to quickly solve the noise and efficiency problems of LPG compressors

To solve the noise and efficiency problems of LPG compressors, it is necessary to systematically consider and implement them from multiple dimensions of equipment, management, and technology. The following are 5 effective optimization solutions that have been tested in practice:

Solution 1: Optimize structural design and material selection

Starting from the source and component materials of LPG compressor design is the fundamental way to reduce noise and improve efficiency.

Refined vibration reduction design:

Foundation vibration reduction: Install high-performance rubber vibration reduction pads, composite vibration reduction devices or spring vibration reduction devices between the compressor and the ground foundation. These vibration reduction devices can effectively absorb and isolate the vibration generated during equipment operation, prevent the vibration from being transmitted to the plant structure or other equipment through the ground, thereby fundamentally reducing structural noise.

Pipeline vibration reduction: The inlet and outlet pipelines of LPG compressors usually generate large vibrations and noise. Flexible connecting hoses (such as bellows) and pipeline vibration reduction brackets should be installed at the connection between the pipeline and the compressor and at the pipeline support point to absorb pipeline vibration and reduce vibration transmission.

Vibration isolation trenches or grooves: Setting vibration isolation trenches or grooves around the compressor foundation and filling them with sound-absorbing materials can further block the vibration propagation path.

Application of efficient sound-absorbing and sound-insulating materials:

Sound-absorbing materials: Lay porous sound-absorbing materials such as polyester fiber sound-absorbing panels, glass wool, rock wool, foam aluminum, etc. on the inner wall of the compressor casing, the inside of the soundproof cover, and the wall of the operating room. These materials can convert sound energy into heat energy, effectively reduce the reflection and reverberation of noise, and thus reduce the overall noise level.

Sound insulation materials: Use high-density sound insulation panels (such as steel plates, concrete plates, and high-density rubber plates) to construct soundproof covers or soundproof rooms. Sound insulation materials mainly achieve sound insulation by hindering the propagation of sound waves. Multi-layer composite material designs, such as the “heavy-light-heavy” structure, can provide better sound insulation performance.

Optimize the design of air flow channel:

Smooth flow channel: optimize the design of the air inlet, exhaust port, valve seat, pipe elbow and other parts of the LPG compressor where the air flows, so that the flow channel is as smooth and round as possible, and reduce sharp angles and mutations.

Reduce flow rate: appropriately increase the cross-sectional area of the pipeline, reduce the LPG gas flow rate, and reduce the aerodynamic noise caused by air flow impact and turbulence.

Eliminate vortex: effectively eliminate the vortex generated by the air flow at high speed through the guide plate or optimize the internal structure, which is an important source of aerodynamic noise.

Improve the processing accuracy and matching quality of parts:

High-precision processing: use advanced processing equipment such as CNC machine tools to ensure the dimensional accuracy and surface finish of key moving parts such as pistons, cylinders, screw rotors, and bearing seats. Precise matching can significantly reduce friction and impact between parts and reduce mechanical noise.

Strict assembly tolerance: strictly control the matching clearance during the assembly process to avoid impact noise and gas leakage caused by excessive clearance, and also avoid increased friction resistance and decreased efficiency caused by too small clearance.

Selection of high-performance materials:

Wear-resistant materials: Piston rings, valve plates, bearings, screw rotors and other easily worn parts should be made of materials with good wear resistance and self-lubricating properties, such as polymer composite materials, special ceramics, alloy steel, etc., to extend the life of the parts and reduce the noise and efficiency loss caused by wear.

Vibration-damping alloys: For some vibration-sensitive parts, vibration-damping alloys with good damping properties can be considered to absorb vibration energy.

Lightweight materials: On the premise of ensuring strength and rigidity, the use of lightweight materials for certain moving parts can reduce inertia force, thereby reducing vibration and noise.

Solution 2: Strengthen daily maintenance and regular maintenance

Scientific and standardized daily maintenance and periodic maintenance are the key to ensuring efficient and stable operation of LPG compressors and significantly reducing failure rates and noise levels.

Refined management of lubrication systems:

Oil selection: Strictly select the lubricant type and grade recommended by the manufacturer to ensure that the lubricant has good chemical stability, lubricity and sealing in the LPG contact environment.

Oil quantity control: Check the lubricating oil level regularly to ensure that it is within the specified range to avoid dry friction caused by insufficient oil or splashing and oil-gas separation caused by excessive oil.

Oil replacement and filtration: Strictly implement the lubricating oil replacement cycle and replace the oil filter regularly to remove impurities and wear particles in the oil, maintain the cleanliness of the lubricating oil and prevent wear.

Oil circuit inspection: Check whether the lubricating oil pipeline has problems such as blockage, leakage or insufficient pumping pressure to ensure that the lubricating oil can be effectively delivered to each lubrication point.

Guarantee of efficient operation of the cooling system:

Cooling medium inspection: Regularly check the flow, temperature and water quality of the cooling water or coolant to ensure the cooling effect. Prevent scaling or corrosion from affecting the heat dissipation efficiency.

Clean the cooler: Clean the air-cooled or water-cooled cooler regularly to remove dust, dirt or scale, ensure the cleanliness of the heat sink and improve the heat dissipation efficiency.

Fan and water pump inspection: Check the operating status of the cooling fan or water pump to ensure that it works normally and provides sufficient cooling capacity.

Tightness inspection of valves and seals:

Regular inspection: For piston compressors, regularly check whether the intake and exhaust valves are deformed, worn, carbon deposited or spring fatigued to ensure the sensitivity and sealing of their opening and closing.

Leak detection: Use professional leak detection tools (such as ultrasonic leak detectors) to regularly check all flanges, joints, pipes and sealing parts for LPG gas leaks, and promptly detect and repair them. Any small leak will lead to reduced efficiency and safety hazards.

Seal replacement: Replace aging seals, gaskets, piston rings and shaft seals in a timely manner according to the manufacturer’s recommendations or actual wear conditions.

Comprehensive inspection and tightening of fasteners:

Prevent loosening: During the long-term operation of the compressor, bolts, nuts and other fasteners are easily loosened due to vibration and thermal expansion and contraction. Regularly check all fasteners such as the body, pipes, motors, safety valves, instruments, etc., and retighten them according to the specified torque. Loose fasteners are an important cause of abnormal noise and vibration.

Real-time monitoring and recording of operating parameters:

Data analysis: Establish a complete equipment operating parameter monitoring system to record and analyze the operating current, voltage, pressure (suction pressure, exhaust pressure), temperature (exhaust temperature, body temperature, lubricating oil temperature), vibration value, noise decibel and other key parameters of the LPG compressor in real time.

Trend analysis: Through the trend analysis of historical data, abnormal fluctuations can be discovered in time, potential faults can be predicted, predictive maintenance can be achieved, and equipment can be prevented from running with illness.

Establish detailed maintenance files:

Traceability: Detailed records are kept for each inspection, maintenance, maintenance, fault diagnosis and repair, including time, operator, inspection content, problems found, solutions, replacement of spare parts, etc. These files are important bases for evaluating equipment status, formulating future maintenance plans and tracing faults.

Solution 3: Introducing advanced noise reduction technology

In addition to starting from the design and maintenance level, directly adopting professional noise reduction technology is a means to quickly and effectively control the noise of LPG compressors.

Integrated soundproof cover/room:

Principle: This is the most direct and effective noise reduction method. By building a completely closed or semi-closed soundproof structure outside the LPG compressor, the noise source is isolated from the outside.

Design points: The wall of the soundproof cover/room should adopt a multi-layer composite structure, with high-density soundproof materials (such as steel plates and cement boards) on the outside and high-performance sound-absorbing materials (such as glass wool, rock wool, polyester fiber) filled inside, and air vents should be set to ensure ventilation and heat dissipation, but the air vents also need to be treated with silencers. Doors and windows should be soundproof and sealed.

Effect: High-quality soundproof covers/rooms can reduce noise by 15-30 decibels or even more, so that noise emissions meet environmental protection standards.

High-efficiency muffler:

Application location: The air inlet and exhaust ports of the LPG compressor are important noise transmission paths, and targeted mufflers should be installed.

Type selection:

Resistive muffler: The interior is filled with porous sound-absorbing materials, and the sound energy is converted into heat energy through the friction and viscosity of sound waves in the pores of the material. It is suitable for medium and high frequency noise.

Resistant silencer: It uses the reflection and interference of sound waves when the pipe cross section changes, expands or contracts to attenuate noise, and is suitable for low and medium frequency noise.

Composite silencer: Combining the principles of resistance and resistance, it has a good attenuation effect on broadband noise.

Design principle: The design of the silencer should take into account the characteristics of LPG gas (flammable and explosive), select explosion-proof and corrosion-resistant materials, and ensure that it has the least impact on the LPG gas flow and pressure loss.

Active noise reduction technology (ANC):

Principle: The active noise reduction system collects environmental noise in real time through a microphone, and then generates a “reverse sound wave” with the opposite phase and the same amplitude as the noise signal. When the reverse sound wave is superimposed on the original noise, the two will cancel each other out, thereby achieving the purpose of noise reduction.

Applicable scenarios: The noise reduction effect on low-frequency noise is particularly significant, which can make up for the shortcomings of traditional passive noise reduction methods. It is often used to control airflow noise in pipelines and low-frequency vibration noise of certain equipment.

Challenges: The cost is relatively high, the system is complex, and precise acoustic modeling and control algorithms are required.

Application of elastic supports and damping materials:

Elastic supports: Install elastic supports (such as rubber vibration damping pads and spring dampers) between the LPG compressor and the ground foundation, as well as at the support points of the pipes connecting the LPG compressor. These elastic elements can effectively isolate vibrations and prevent vibrations from propagating through solid structures, thereby reducing structural noise.

Damping materials: Coat or paste damping materials on the surface of plates or structural parts with large vibrations. Damping materials can convert the vibration energy of structural parts into heat energy and dissipate it, thereby reducing the vibration amplitude and radiated noise. For example, damping sheets can be pasted on the outer thin plate of the compressor.

Solution 4: Optimize operating procedures and personnel training

Even if you have the most advanced equipment, it will not perform at its best if it is not operated properly. Optimizing operating procedures and improving personnel quality are soft powers to improve the efficiency of LPG compressors and reduce the failure rate.

Precise load control:

Avoid no-load/light-load operation: When LPG compressors are running at low load or no load, their energy consumption per unit gas output will increase significantly and their efficiency will drop sharply. According to the actual LPG gas demand, the compressor start and stop should be reasonably planned or variable frequency speed regulation technology should be adopted (see Plan 5) to avoid unnecessary no-load or light-load operation.

Optimize multi-machine joint control: If multiple LPG compressors are running in parallel, an intelligent control system should be used for optimized scheduling to ensure that each compressor runs in the best efficiency area as much as possible to avoid “big horse pulling a small cart” or frequent start and stop.

Standardized start and stop procedures:

Strictly follow: Establish and strictly implement standardized start and stop operating procedures for LPG compressors. Irregular start and stop, such as no preheating, sudden loading or emergency stop, will bring huge impact and stress to the equipment, accelerate component wear, and even cause failure.

Gradual loading/unloading: Ensure gradual loading during startup and gradual unloading during shutdown to give the equipment enough buffer time.

Dynamic adjustment of operating parameters:

According to changes in operating conditions: LPG operating parameters such as temperature, pressure, and gas consumption will change with factors such as seasons and production needs. Operators should learn to dynamically adjust the operating parameters of the compressor, such as suction pressure, exhaust pressure, cooling temperature, etc., according to these changes, so that it always operates near the designed high-efficiency zone.

Reference performance curve: Familiar with the performance curve of the compressor and understand the efficiency performance under different parameter combinations.

Comprehensive training of operators and maintenance personnel:

Systematic theoretical knowledge: Organize systematic theoretical knowledge training on the working principle, structural composition, system flow, etc. of LPG compressors for operators and maintenance personnel to enable them to have a deep understanding of the equipment.

Operation skills training: Conduct practical operation skills training, including correct start and stop of equipment, operation monitoring, parameter adjustment, fault judgment and emergency handling.

Maintenance skills: Train maintenance personnel to master the inspection, maintenance and simple troubleshooting skills of lubrication, cooling, sealing, valve, electrical and other systems.

Safety awareness enhancement: Special emphasis is placed on the particularity of LPG as a flammable and explosive medium, and safety awareness and emergency plan drills are strengthened to ensure that operators can deal with emergencies proficiently.

Continuous learning: Encourage and support employees to participate in industry exchanges and technical seminars to keep their knowledge and skills updated.

Solution 5: Upgrading and technological innovation

For old or inefficient LPG compressors, upgrading and renovating by introducing modern advanced technology is the fundamental way to achieve a leap in performance and an investment for the future.

Application of variable frequency speed regulation technology:

Principle and advantages: The frequency converter can automatically and accurately adjust the speed of the LPG compressor motor according to the actual demand for LPG gas consumption, thereby changing the compressor’s gas supply. When the gas consumption decreases, the motor speed decreases and the energy consumption also drops significantly. Compared with the traditional “load/unload” or “start-stop” control method, frequency conversion technology can keep the LPG compressor running in the high-efficiency zone, significantly saving electricity (usually up to 20%-40%).

Additional benefits: The variable frequency starting current is small and the impact on the power grid is small; soft start/soft stop reduces mechanical impact and extends equipment life; precise pressure control makes the system pressure more stable.

High-efficiency and energy-saving motor replacement:

IE3/IE4 motor: Replace the traditional ordinary motor with an energy-saving motor that meets the IE3 (high efficiency) or IE4 (super high efficiency) standards. These motors use optimized design and materials to convert more electrical energy into mechanical energy, reduce heat loss, and thus improve overall efficiency. Although the initial investment is slightly higher, the long-term energy-saving benefits it brings are very considerable.

Intelligent control system (SCADA/DCS) integration:

Automation and intelligence: Introduce advanced SCADA (data acquisition and monitoring system) or DCS (distributed control system) to conduct real-time and comprehensive data collection, monitoring, analysis and control of the operating status of LPG compressors.

Optimized operation: The system can automatically optimize the start and stop sequence, load distribution, pressure control, temperature regulation, etc. of the compressor according to the preset logic and algorithm to ensure that the compressor cluster always operates in the most energy-efficient way.

Remote monitoring and fault diagnosis: Realize remote monitoring and management, and have fault warning, diagnosis and alarm functions, greatly improving the operating reliability and management efficiency of the equipment.

Residual heat recovery and utilization:

Energy saving potential: LPG compressors generate a lot of heat during operation, especially oil-injected screw compressors, whose exhaust temperature is usually high. If these waste heat are directly discharged, it will be a huge waste of energy.

Recovery method: By installing waste heat recovery devices (such as heat exchangers), these waste heat can be used to heat production water, heating, or other process to achieve cascade utilization of energy. This can not only effectively reduce the energy cost of the enterprise, but also conform to the concept of green production.

Upgrading of key components:

New generation of valves: For piston compressors, you can consider replacing them with new high-efficiency and low-resistance gas valves to reduce gas resistance, reduce pressure loss, and improve volumetric efficiency.

New bearings and seals: Use more advanced bearing and seal materials with lower friction coefficient and longer life to reduce mechanical friction loss and extend maintenance cycle.

Flow channel optimization and improvement: Partially modify the gas flow channel inside the existing compressor, such as grinding and polishing, adding guide parts, etc., to further reduce flow resistance and aerodynamic noise.

Conclusion

As a key energy conversion equipment, the noise and efficiency issues of LPG compressors are directly related to the company’s operating costs, employee health and environmental compliance. Solving these problems is not a one-off task, and requires companies to systematically plan and invest in multiple aspects such as equipment design, daily maintenance, technological innovation and operation management.

The five optimization solutions described in this article – including optimizing structural design and material selection to reduce noise and wear from the source, strengthening daily maintenance and regular maintenance to ensure continuous and efficient operation of equipment, introducing advanced noise reduction technology to directly control noise pollution, optimizing operating procedures and personnel training to improve human-machine collaboration efficiency, and upgrading and technological innovation to achieve a fundamental leap in performance – are all effective ways that have been verified in practice.

By scientifically evaluating the specific conditions of their own LPG compressors, combining actual needs and budgets, and selecting and implementing one or more of the above optimization solutions in a targeted manner, companies will be able to significantly reduce the noise level of LPG compressors, greatly improve their operating efficiency, and thus reduce energy consumption and maintenance costs, extend the service life of equipment, and ultimately achieve the goals of improving the production environment, improving economic benefits, and achieving green and sustainable development of the company. Investing in the optimization of your LPG compressor is undoubtedly a smart move with huge returns.

.png)